The Duravant family of operating companies serve the food processing, packaging and material handling segments.

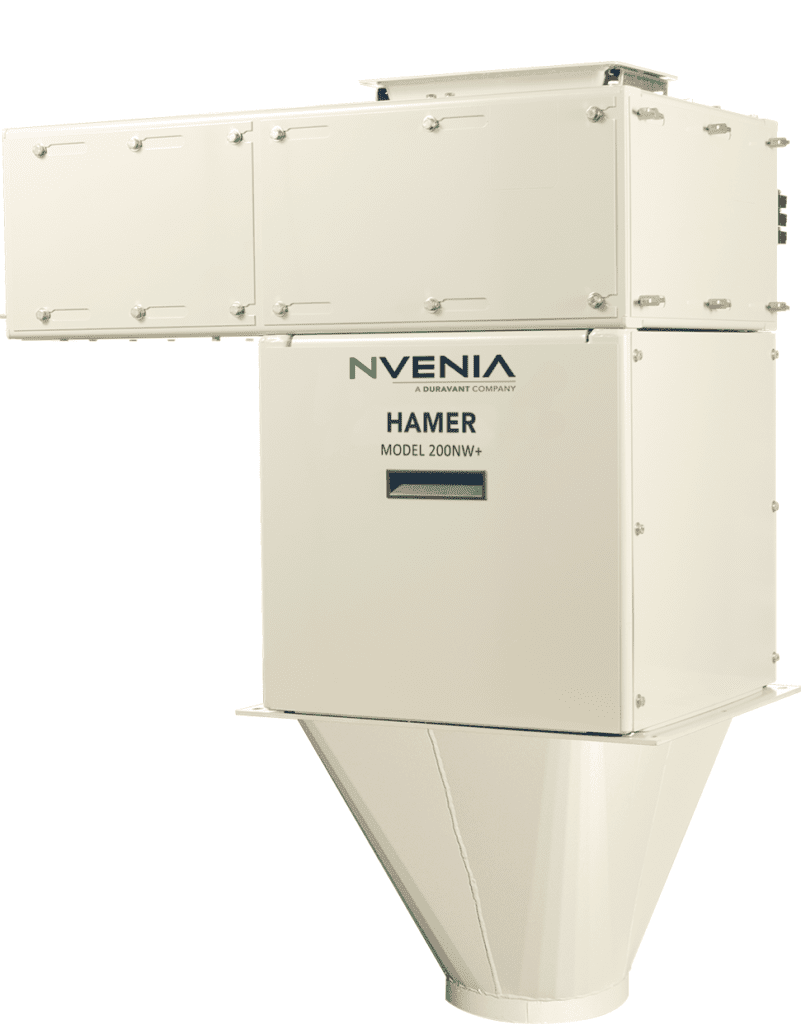

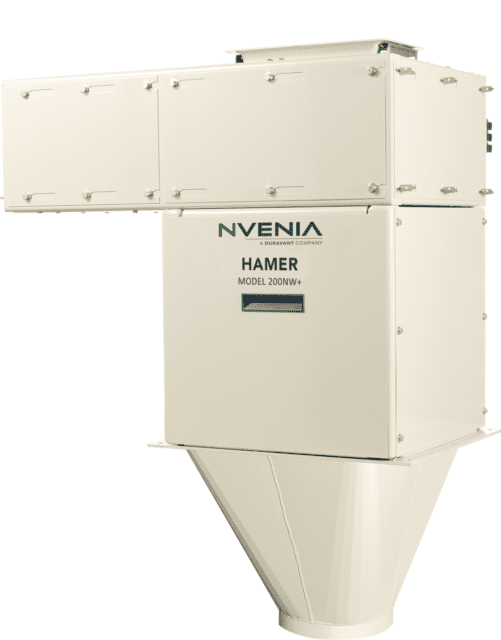

Báscula de peso neto modelo 200NW + de la marca Hamer

El modelo 200NW + de Hamer ofrece una dosificación de calidad industrial para trabajos pesados de pequeños pesajes. El modelo 200NW + puede procesar con precisión pesajes de .5 a 28-30 lb en configuraciones Simplex, Duplex o Quad y está disponible con construcción de acero estructural, superficies de contacto de acero inoxidable o construcción de acero inoxidable completo. Están disponibles configuraciones de alimentación por gravedad tanto neumáticas como servocontroladas.

Estás interesado en este producto?

Nosotros estamos aqui para ayudar.

Features

- Pesaje de alta precisión: hasta +/- 0.5 oz (15 g) @ 2 sigma

- Tolva de pesaje de acero de calibre pesado

- Las puertas empinadas de la tolva de pesaje garantizan una descarga rápida del producto con un mínimo de residuos

- Diseño de celda de carga dual que ofrece mayor precisión y velocidad

- Superficie de contacto de acero inoxidable y construcción completa de acero inoxidable disponibles

- Las puertas de la tolva de pesaje de acero reforzado aumentan la vida útil

- Puerto (s) de recolección de polvo de 4 “

- Amortiguación de cargas mecánicas

- Células de carga de un solo punto tipo plataforma resistente

- Cilindros de aire industriales, válvulas y neumática

- Paneles laterales de báscula extraíbles de fácil acceso

- Paneles extraíbles de fácil acceso para opciones de alimentador

- Indicador de báscula electrónico de alta resolución con control de peso programable, indicadores de estado de la báscula, estado de nivel de llenado de sobretensión / tolva / silo

- El controlador almacena hasta 100 fórmulas preestablecidas

- Caja del controlador NEMA 4X 304SS

- Salida de comunicaciones RS-232/485 a impresoras y otros dispositivos

- Controlador aprobado por UL, CUL, OIML y NTEP

Standard Specs

Standard Specs

Dimensiones

Escala:

Longitud: 44 “

Ancho: 20 “

Altura: 32 “

Tolva de pesaje:

0.8 cu. pie

Dimensiones de la bolsa

Ancho mínimo: 8 in

Velocidad

Hasta 30 BPM Servo Gravity Simplex

Hasta 26 BPM Gravity Simplex

Rango de peso del producto

113 g (0,25 libras) a 13,6 kg (30 libras)

Requisitos eléctricos

110 VCA, monofásico, 60 Hz, 5 A

230VAC, 1 PH, 60 Hz, 5A opcional para servo de gravedad

50 Hz opcional

Requisitos de aire

10 cfm a 80 psi

Accessories

Accessories

OPCIONES:

- Configuraciones simplex, dúplex o cuádruple

- Boquillas para ensacado manual: agarre central, a prueba de polvo o con forma de almeja

- Construcción de acero inoxidable 304

- Puntos de contacto de productos de acero inoxidable 304/316

- Sensor de nivel de capacitancia (contacto con producto de acero inoxidable o completamente inoxidable)

- Células de carga herméticamente selladas de acero inoxidable

- Actualización de servo gravedad

- Paquete de control de reemplazo 920i

- Sensor de paleta giratoria

- Control de pedal

- Conductos de clasificación para ensacado manual o automático en acero dulce o acero inoxidable

- Revestimiento de tolva de UHMW

- Acabado de pulido de superficie en el balde de pesaje

- 50 Hz de potencia

- Conectividad Ethernet

- Escala de estructuras de soporte

- Transportadores de bolsas llenas, cierres superiores de bolsas

- Sistemas de ensacado automatizados