The Duravant family of operating companies serve the food processing, packaging and material handling segments.

Preventive Maintenance Checklist – Horizontal Form Fill Seal

04/19/2019

Preventive Maintenance of your horizontal form, fill and seal packaging equipment helps to extend the life of your machine and maximize its production capabilities. Regularly scheduled preventive maintenance structured to meet your horizontal form, fill and seal’s specific needs can keep your production line up and running and minimize costs lost due to unnecessary downtime. For optimum results, preventive maintenance schedules should be outlined on a daily, weekly, monthly, and seasonal basis.

Horizontal Form Fill Seal Preventive Maintenance – Seasonal

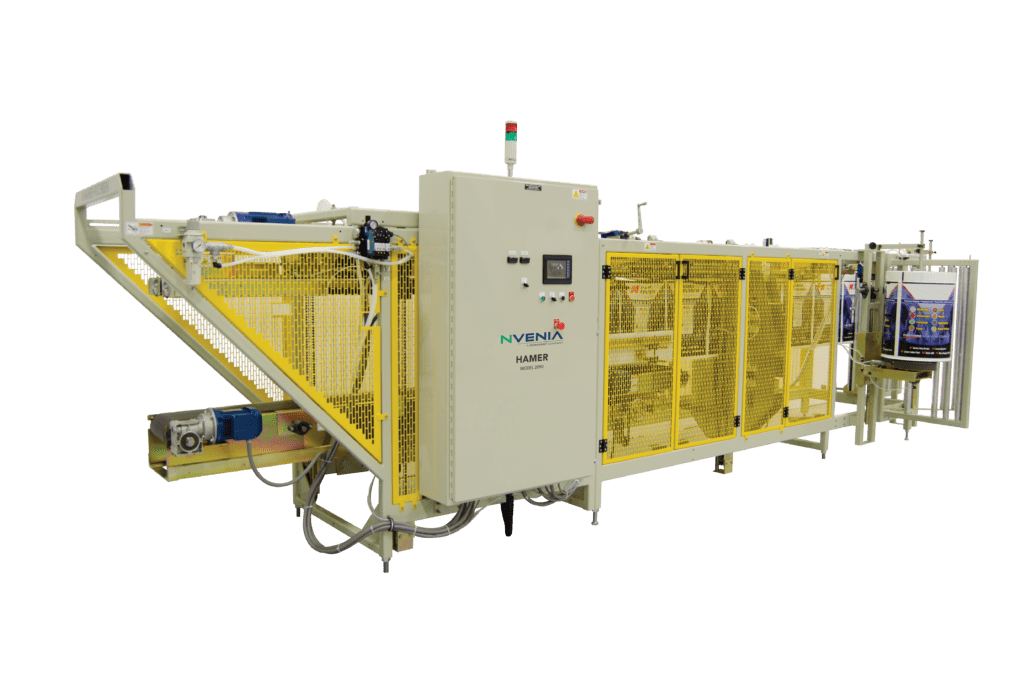

The following is a list of tasks that should be performed on your nVenia HAMER Brand Model 2080/2090 FFS before each packaging season:

- Replace film feed belts and lubricate all slide mechanisms

- Replace vertical heat seal Teflon and silicone rubber backup

- Replace perforator blade and silicone backup

- Check all bearings and replace any that do not operate smoothly

- Check all air cylinders for any air leaks and replace or rebuild cylinders as needed

- Check chains and sprockets for proper tension or wear and replace if needed

- Verify all areas of the machine are set back to the original manufacturer’s specifications

- Check belt lagging on conveyor rollers for wear (replace if needed)

- Check oil level in the gear boxes (add oil if needed)

- Check sprockets for wear (replace if needed)

For more preventive maintenance tips and information on maintaining and servicing your Horizontal Form Fill and Seal equipment, contact our team at Support@nVenia.Pro