The Duravant family of operating companies serve the food processing, packaging and material handling segments.

Automation in Manufacturing

08/03/2023

Automation has revolutionized the manufacturing industry, providing numerous advantages that enhance production efficiency and profitability. Automated systems have the ability to replace labor-intensive processes and perform operations with increased accuracy and consistency, resulting in higher quality output. In this article, we will explore some of the key advantages of automation in manufacturing.

Consistency in Output

One of the most significant advantages of automation in manufacturing is the consistency it brings to the production process. Automated systems are designed to perform tasks with exact precision, eliminating the potential for human error. This results in a consistent level of quality output, which is essential in many industries. Consistent output leads to higher customer satisfaction and improved brand reputation.

ROI and Cost Savings

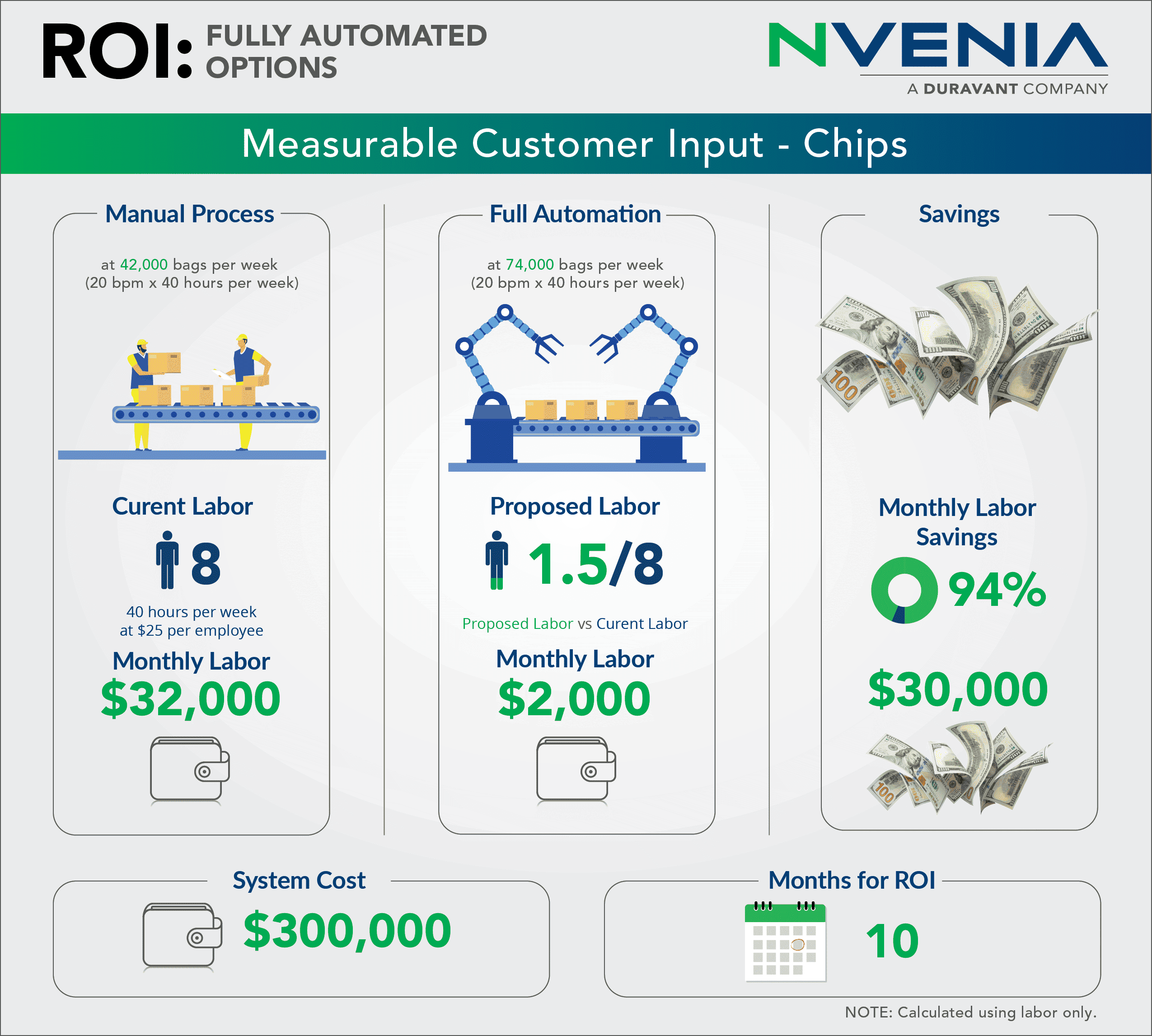

Automated systems can provide a significant return on investment (ROI) and cost savings in the long run. Although the initial investment may be greater compared to manual labor, automated systems do not carry the same costs and risks and are designed to operate for longer periods without breakdowns or errors. Additionally, they can safely operate at faster speeds, reducing production time and increasing throughput. The reduction in labor cost and risk, coupled with the improved efficiency of the production process translates into significant cost savings.

Reduced Giveaway Rates

Another advantage of automation in manufacturing is the reduction of giveaway rates. With hand-filling or manual packaging, there is a higher potential for errors in measurement, which can lead to product loss. This can be especially costly in industries where raw materials are expensive, and there is a high demand for the final product. Automated systems, on the other hand, are designed to perform accurate measurements, reducing the risk of product loss and increasing yield.

Production Increase

Automated systems are designed to operate at faster speeds than manual labor, resulting in increased production rates. Automated systems can also run 24/7, allowing for continuous production, which is especially beneficial in industries with high demand. This increase in production can lead to higher revenue and greater market share.

Labor Savings

One of the most obvious advantages of automation in manufacturing is labor savings. Automated systems can replace manual labor, reducing the need for human workers for certain tasks. This not only reduces labor costs, but also eliminates the potential for human error and injury. Automated systems also require less supervision and can operate independently, freeing up labor for other tasks.

Automation in manufacturing offers numerous advantages that can enhance production efficiency and profitability. Consistent output, ROI and cost savings, reduced giveaway rates, production increase, and labor savings are just a few of the many benefits of automation. As technology continues to advance, we can expect automation to become even more prevalent in the manufacturing industry, further improving production processes and driving industry growth.

As you can see from the infographic accompanying this article, the entire initial cost of implementing an automated system can be recovered in a matter of months. Once you have recouped your initial investment, you will reap the benefits of increased outputs at reduced costs for years to come. Please contact nVenia today and our experts will custom-engineer an automated production solution for you that will pay for itself many times over.