The Duravant family of operating companies serve the food processing, packaging and material handling segments.

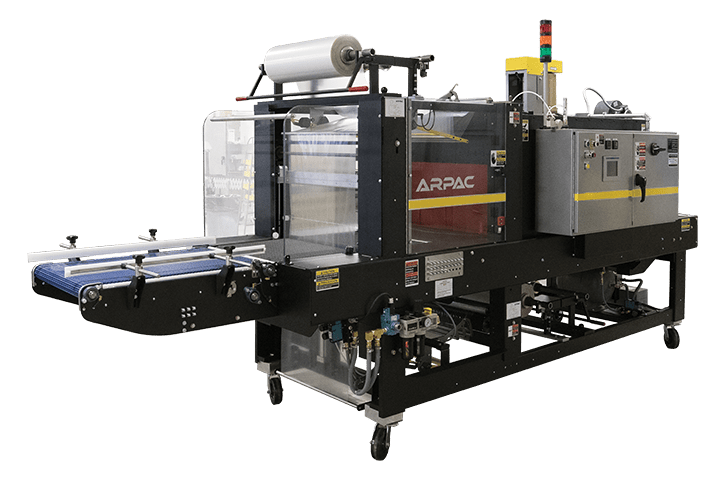

Arpac Brand 25TW Model Tray Wrapper

Our Arpac Brand 25TW Model is an intermittent motion tray wrapper capable of wrapping up to 25 products per minute, depending on product size. It’s rugged design ensures years of reliable service.

It is ideal for wrapping a wide range of products in either a single tier or stacked arrangement, such as:

- Cans

- Jars

- Floor tiles

- Plastic bottles

- Glass bottles

- Plates

Are you interested in this product?

We are here to help.

Features

Standard

- Heavy-duty rugged construction designed for high durability and around-the-clock operation

- Laser cut and CNC machined components for maximum precision

- Durable, scratch resistant powder coat finish

- Allen-Bradley® PanelView Plus600 operator interface with color touchscreen, message display and self-diagnostics

- Digital controls for fast and accurate setup when changing product size and film

- Single stage belt infeed conveyor for smooth and gentle product handling

- Durable Intralox conveyor belts eliminate tracking problems

- Bypass mode allows product to pass through the machine without being wrapped and without heating the tunnel

- Dual 14″ dia. inline telescoping film racks for easy film loading

- Simple film threading procedure

- Easy access heater elements

- Compact, single frame design (wrapper with integrated tunnel)

- Turbo cooling feature for immediate product handling

- NEMA 12 electrical cabinet and controls

- Low film alert warns that a film changeover will soon be necessary

- Central point lubrication simplifies preventive maintenance

Options

- Casters for easy machine portability

- Quick-change seal frame cylinder kit for higher speeds

- Pacing conveyor

- Low tension film assist

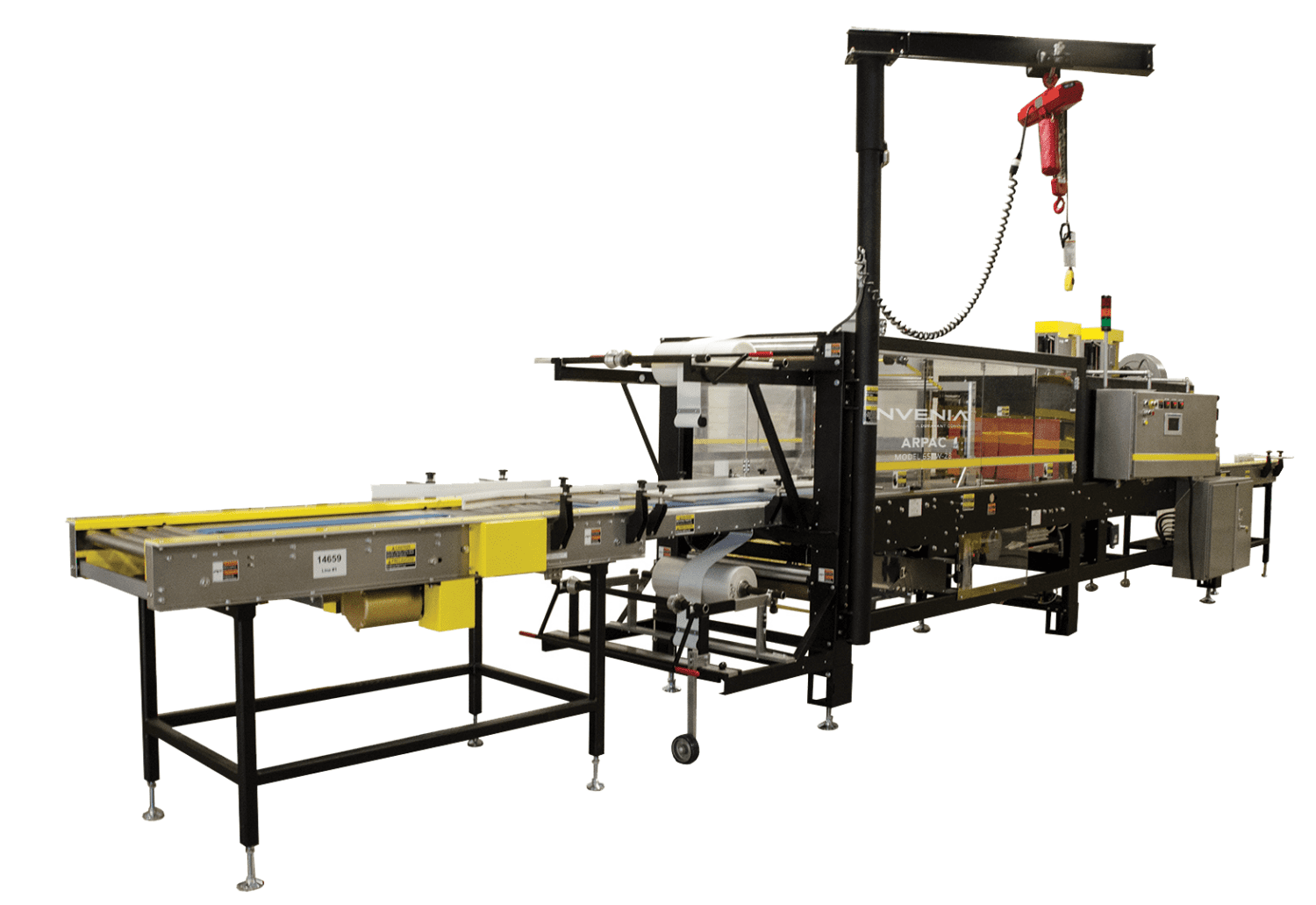

- Jib crane to assist with film loading

- Alternate seal frame opening changes product height range to 2″-10″

- Alternate voltages available: 8VAC, 230VAC, 575VAC

- Print registration – top film only

- Single or dual film cradle

- Right angle pusher w/conveyor into machine

- Seal Gap Bridge – roller or telescoping for product 3″-6″ long

Standard Specs

Standard Specs

Speed

Up to 25 trays per minute depending on application

Electrical Power Requirements

460VAC, 3Ph, 60Hz, 35A

Compressed Air Requirements

80 psi, 15 SCFM

Product Range

Minimum: 6″W x 7″ L x 4″ H

Maximum: 18″ W x 20″L x 12″ H

Film Roll Diameter

up to 14″ with a 3″ core

Film Gauge

Up to 3 mil. maximum

Film Type

Low density polyethylene (L.D.P.E.)

Other Film Specifications

Clear or randomly printed

Machine Dimensions

60″ W x 140″ L x 77″ H

Shipping Weight

~2,500 lb