The Duravant family of operating companies serve the food processing, packaging and material handling segments.

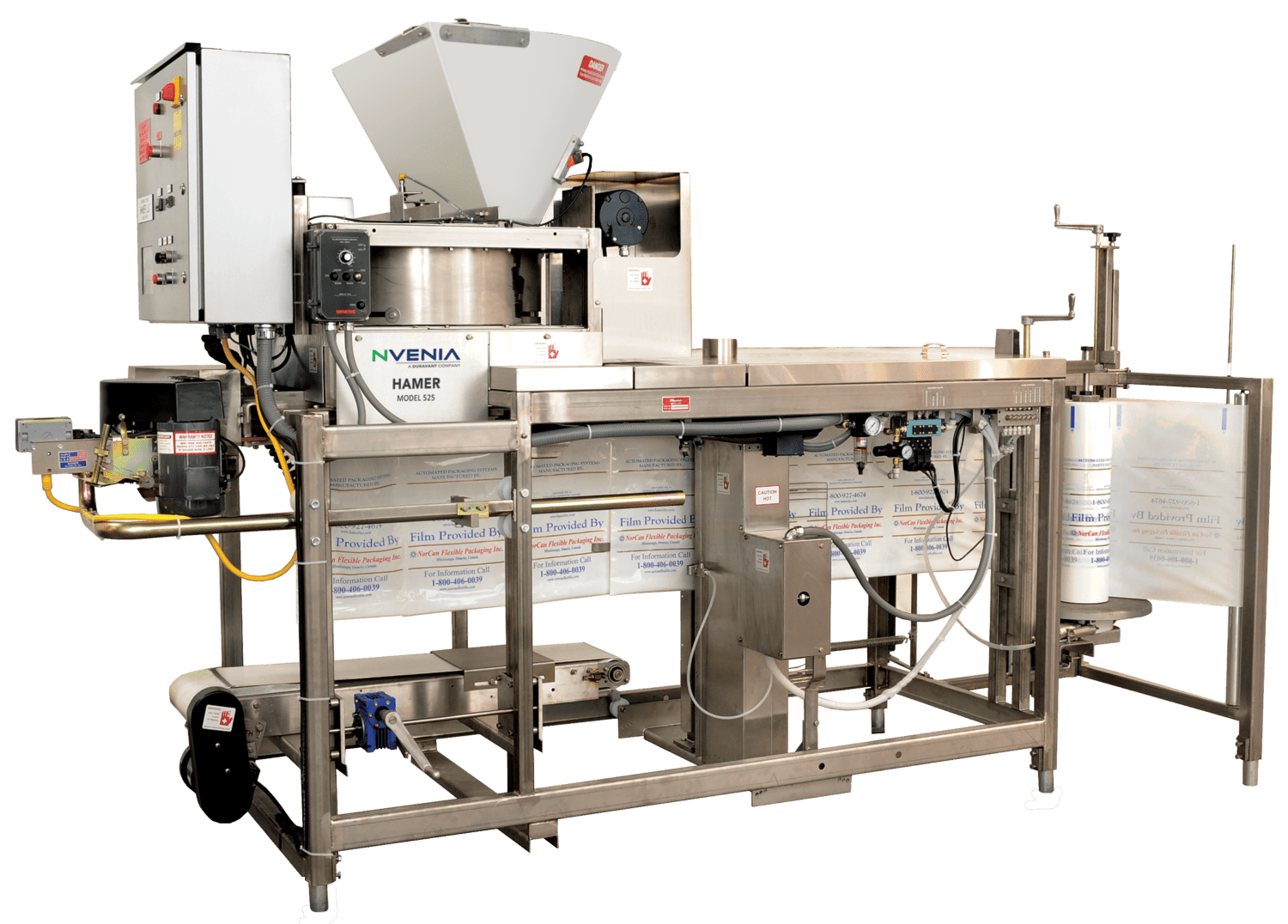

Hamer Brand 540E Form, Fill and Seal (FFS) Packaged Ice Machine

Recently updated with a number of usability and reliability enhancing features, the Hamer Brand 540E packaged ice bagging machine provides versatility and high speed automation for packaged ice production. The machine enables forming, filling and sealing of all popular bag sizes with the flexibility to add features such as gussets and in-bag handles. The machine comes complete with a 304 stainless steel volumetric filler with a food grade UHMW lining and variable speed controls for high speed ice dosing. The hot air top seal consumes 10% less energy than similar wire tie machines at speeds up to 50 bags per minute. The touch screen HMI simplifies operator training and machine operation.

The recent enhancements to the machine include:

- VFD/Servo belt drive for the film feed – providing greater control and accuracy as well as lower maintenance and longevity of components

- Improved side seal access and bag stripper bar adjustments – reducing the frequency and complexity of regular adjustments to the side seal

- Consolidation of pneumatics and wiring to common locations with clearly labeled terminal blocks – simplifies troubleshooting and enhances machine reliability for greater uptime

- Updated HMI with a larger screen and native Spanish language support and HMI controlled top seal heaters

- 230V/3Ph standard

- A pneumatic core chuck option to better control film position from beginning to end of roll

Are you interested in this product?

We are here to help.

Features

- 304 stainless steel frame and product contact surfaces

- Easy Run™ hot air seal bag top closing reduces film use

- VFD/Servo film feed

- Touchscreen HMI with English/Spanish language support

- 15″ vertical roll holder

- AC variable speed heat sealer and volumetric feeder

- Automatic bag venting

- Easy view low product level light

- Handheld remote control

Standard Specs

Standard Specs

Bag Sizes

Width: 11″ to 18″

Length: 14″ to 35″

Weight: 5 lb/2 kg to 40 lb/20 kg

Thickness: 1.75 mil to 4 mil

Speed

Up to 50 BPM

Power Requirements

230 VAC,3 Ph, 60 Hz, 35 A

Air Requirements

32 CFM @ 80 PSI clean/dry air

Note: air consumption increases with some applications

Accessories

Accessories

OPTIONS:

- Pneumatic core chuck

- Date coders

- Inkjet printer

- Bag bottom gusset former

- Bag top trimmer

- Handle former

- Speed up kit

- 35″ roll holder

- Core lift chuck for 35″ rolls

- 35″ portable roll stand

- Caster kit

- 50 Hz electrical