The Duravant family of operating companies serve the food processing, packaging and material handling segments.

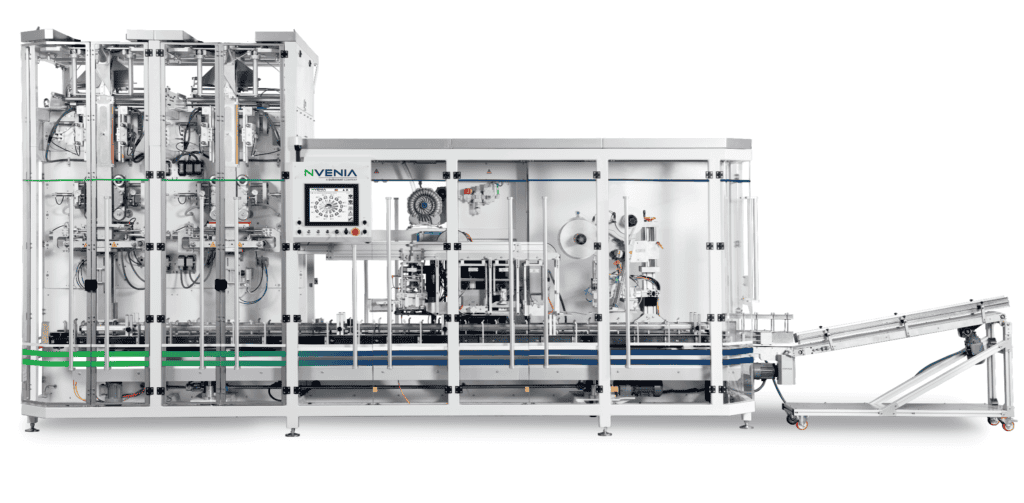

Optima Series Intermittent Motion Vertical Form, Fill & Seal Baggers

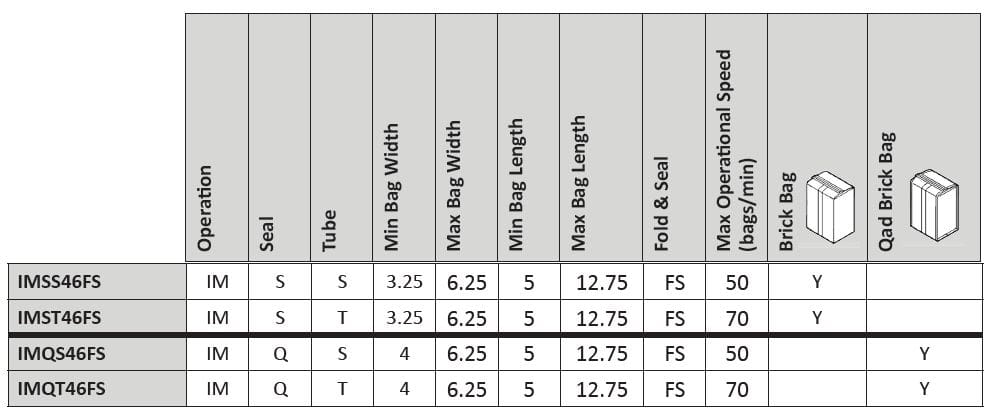

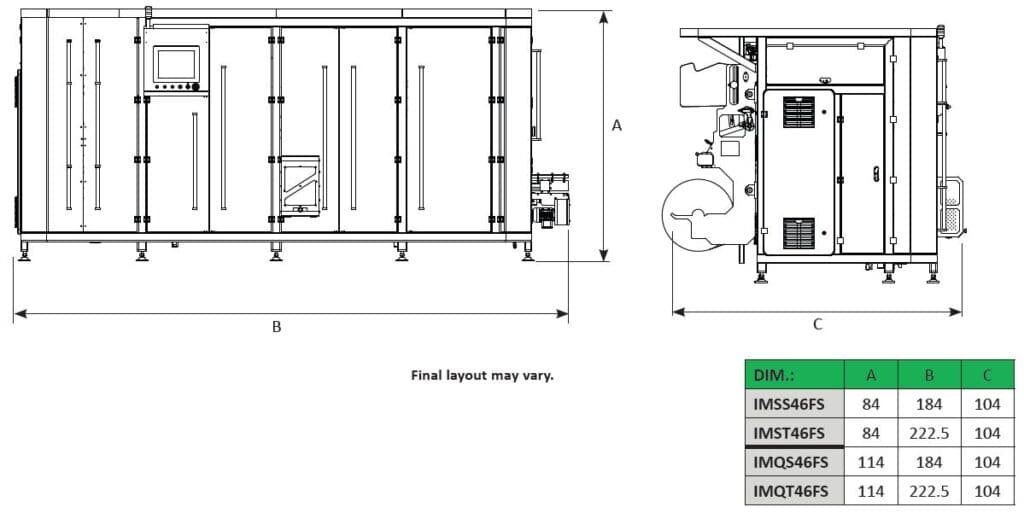

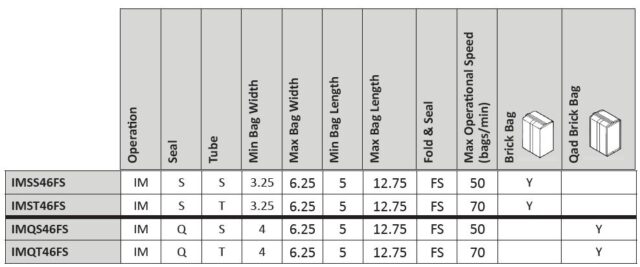

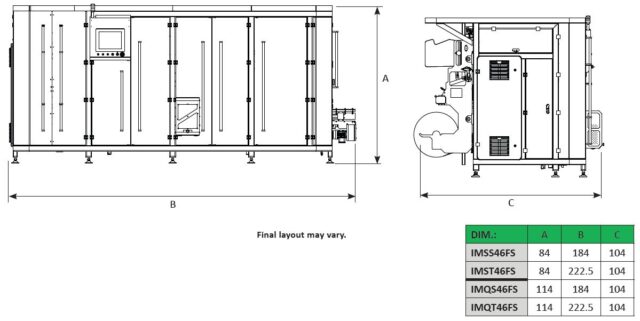

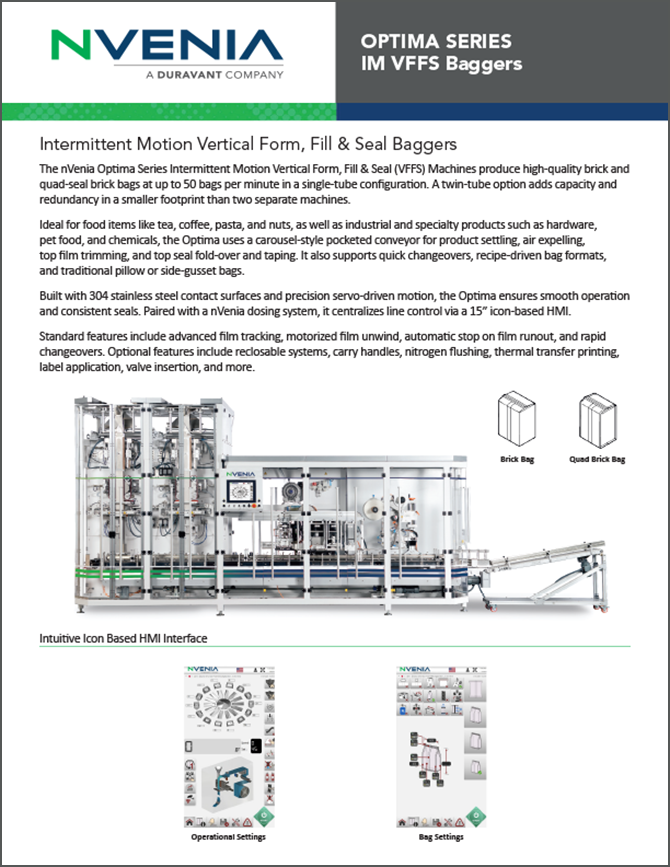

The nVenia Optima Series Intermittent Motion Vertical Form, Fill & Seal (VFFS) Machines produce high-quality brick and quad-seal brick bags at up to 50 bags per minute in a single-tube configuration. A twin-tube option adds capacity and redundancy in a smaller footprint than two separate machines.

Ideal for food items like tea, coffee, pasta, and nuts, as well as industrial and specialty products such as hardware, pet food, and chemicals, the Optima uses a carousel-style pocketed conveyor for product settling, air expelling, top film trimming, and top seal fold-over and taping. It also supports quick changeovers, recipe-driven bag formats, and traditional pillow or side-gusset bags.

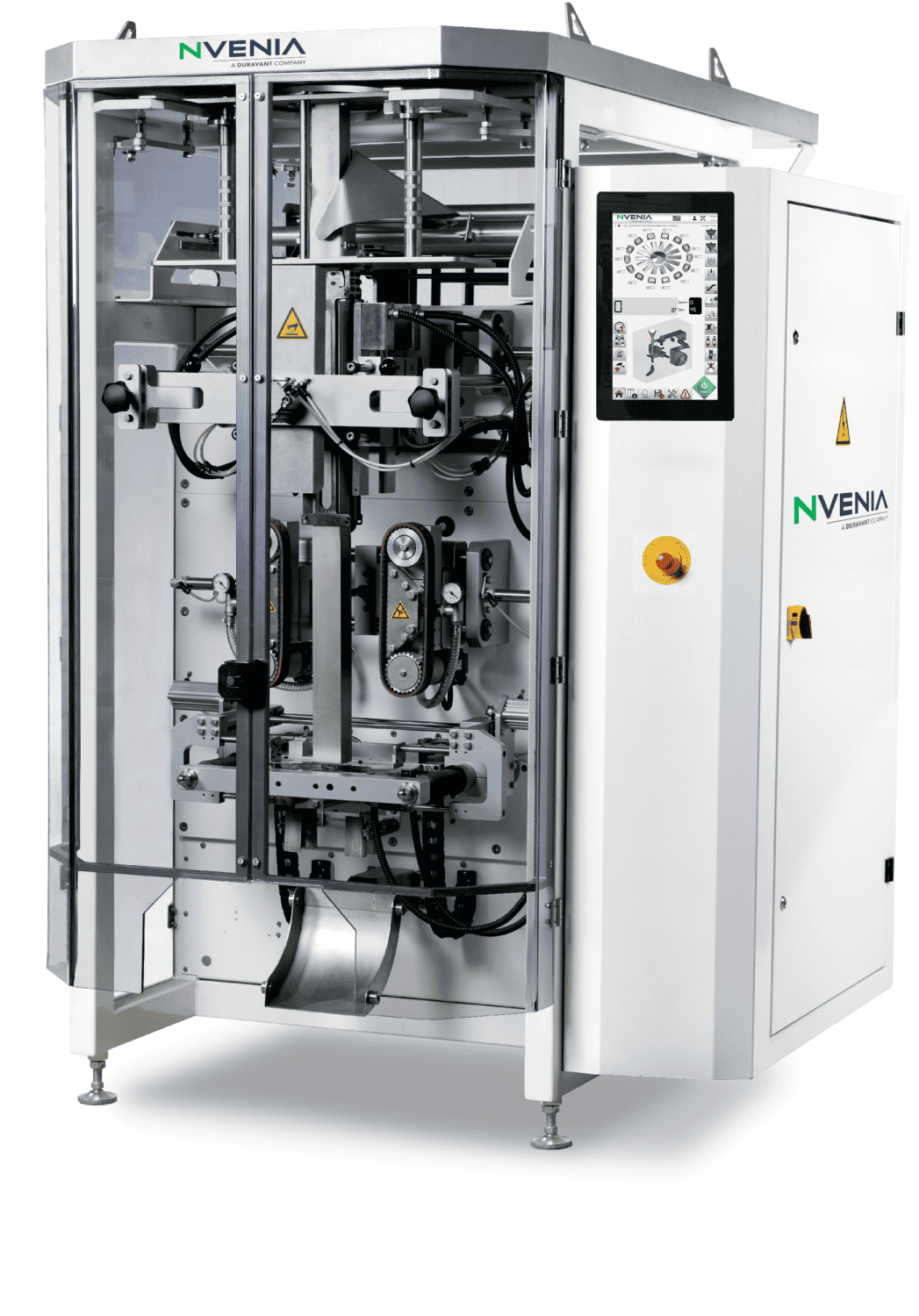

Built with 304 stainless steel contact surfaces and precision servo-driven motion, the Optima ensures smooth operation and consistent seals. Paired with a nVenia dosing system, it centralizes line control via a 15” icon-based HMI.

Standard features include advanced film tracking, motorized film unwind, automatic stop on film runout, and rapid changeovers. Optional features include reclosable systems, carry handles, nitrogen flushing, thermal transfer printing, label application, valve insertion, and more.

Are you interested in this product?

We are here to help.

Features

Features

• Intuitive 15” icon-based HMI with centralized line control when paired with a nVenia dosing system

• Speeds up to 50 bags per minute in single-tube configuration

• Flexible bag formats, including brick, pillow, and side-gusset styles

• Servo motors on all major motion points for precision and reliability

• Tool-less changeover for film rolls, forming tubes, and seal jaws

Standard Specs

Standard Specs

Specifications

• 480 VAC 3-Phase 60Hz

• 10 CFM 90PSI Clean Dry Air