The Duravant family of operating companies serve the food processing, packaging and material handling segments.

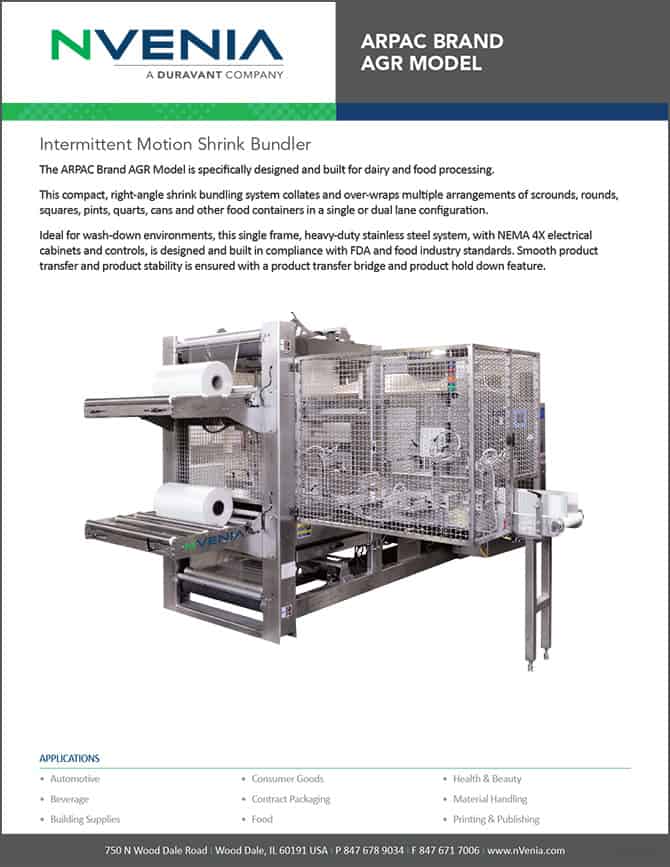

Arpac Brand AGR Model Shrink Bundler

Our Arpac Brand AGR Model is specifically designed and built for the dairy and frozen food industry.

This compact, right-angle infeed shrink bundling system collates and over-wraps multiple arrangements of scrounds, rounds, squares, pints, quarts, cans and other food containers in a single or dual lane configuration.

Ideal for wash-down environments, this single frame, heavy-duty, stainless steel system, with NEMA 4X electrical cabinets and controls, is designed and built in compliance with FDA and food industry standards. Smooth product transfer and product stability is ensured with a product transfer bridge and product hold down feature.

Are you interested in this product?

We are here to help.

Features

Standard

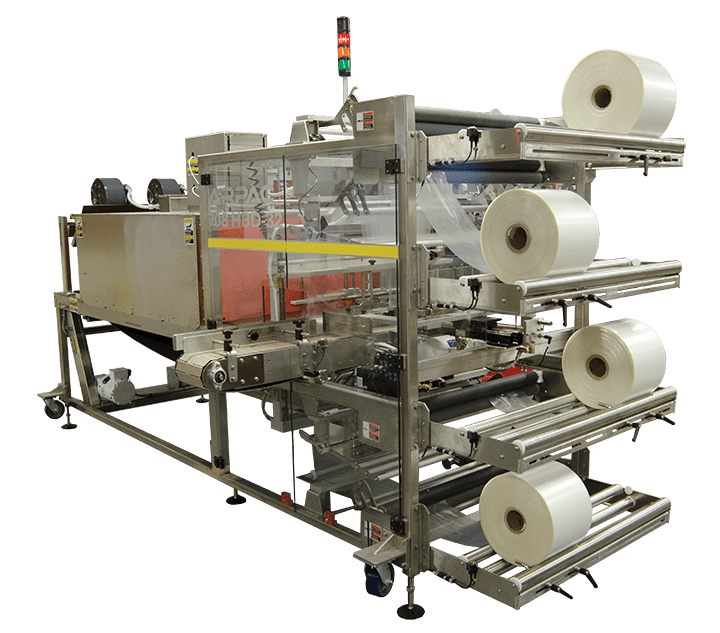

- Low profile, compact, single frame construction designed for 24/7 operation

- Heavy-duty tubular stainless steel frame for wash-down environments

- Stainless steel mesh guarding with safety switches

- Independently driven film feed rollers with easy threading feature

- Dual roll top and bottom film cradles

- NEMA 4X electrical controls and cabinets

- Direct driven conveyor belts

- Rodless cylinder main ram

- Product hold-down for light or unstable product

- Transfer bridge plate for smooth product transition through seal gap

- Easy access pullout heater elements

- Triple insulated high velocity shrink tunnel

- High temperature plastic, sprocket driven tunnel belt

- Cooling section at tunnel exit for immediate product handling

Options

- Custom product collation infeeds

- Servo driven main ram or servo driven seal frame

- Automatic product inverter

Product Range Collation Options

- Pints: 3×2 4×2

- Quarts 3×2 2×3

- Tubs 2×1 2×2

- Scrounds 3×1 3×2

- Round 3×1 3×2

- Squares 3×1 3×2

Standard Specs

Standard Specs

Speed

Output speed: up to 25 packages per minute

Electrical Power Requirements

460VAC, 3Ph, 60Hz

Compressed Air Requirements

80 psi @ 10 SCFM

Film Width

27″ maximum

Film Roll Diameter

Up to 14″ with 3″ Core

Film Type

1-2 mil Low density polyethylene (L.D.P.E.)

Clear or Print Registered