The Duravant family of operating companies serve the food processing, packaging and material handling segments.

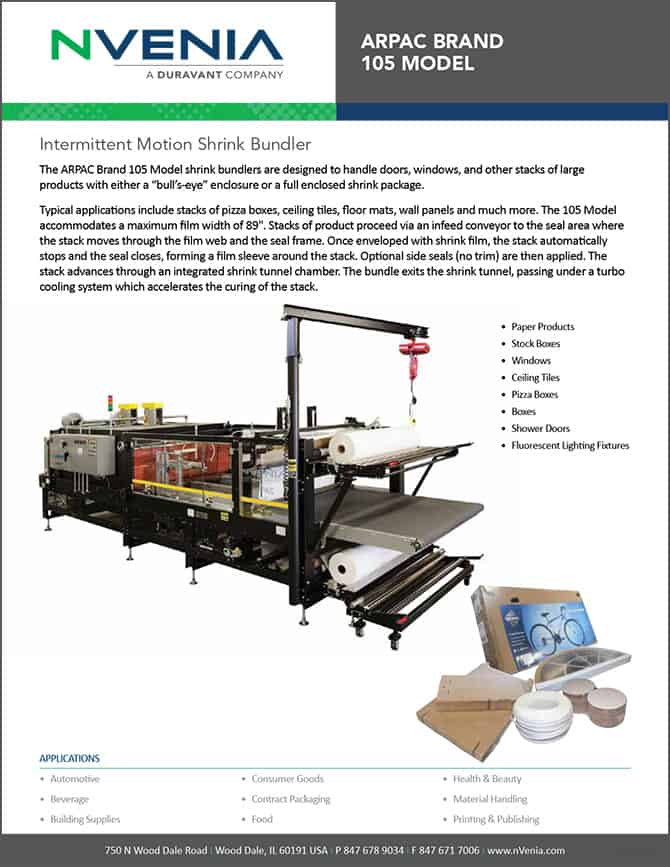

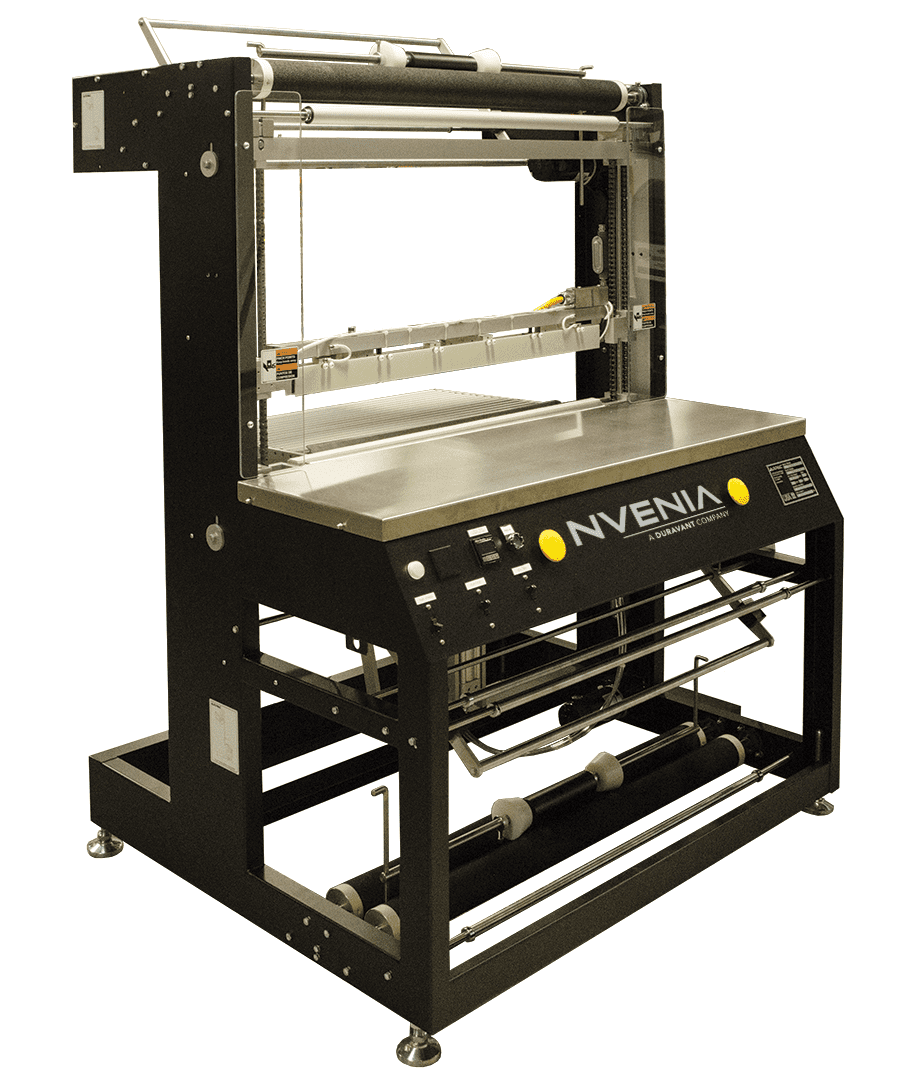

Arpac Brand 105/125 Series Shrink Bundlers

Our Arpac Brand 105/125 series shrink bundlers are rugged shrink bundling systems designed for around-the-clock operation in the most demanding production environments. These bundlers are ideal for wrapping a wide variety of large products including stacks of corrugated blanks, windows, doors, ceiling tiles, wall panels, floor mats, distribution bundles of boxed products and more with the ability to dynamically adjust conveyor width and square products.

Are you interested in this product?

We are here to help.

Features

Standard

- Heavy-duty rugged construction designed for high durability and 24/7 operation

- Powder coat finish that provides a durable scratch resistant surface and prevents corrosion

- Can produce both bullseye and side seal package enclosures

- Integrated dual stage shrink tunnel (or separate frame for larger systems)

- Top and bottom film racks utilize less floor space

- Quick and easy changeovers of different product sizes

- Allen Bradley® programmable logic controller

- Central point lubrication for routine maintenance without interrupting production

Options

- Side mounted film cradles

- Servo driven seal frame

- Print registration

- Side seal and film trim with scrap removal

- Squaring device for product orientation alignment

Standard Specs

Standard Specs

Speed

Electrical Power Requirements

460 VAC, 3 Ph, 60Hz

Compressed Air Requirements

80 psi, 15 SCFM

Product Requirements

A wide variety of product heights and widths can be accommodated due to the highly flexible nature of this platform. Please contact your local nVenia Regional Sales Manager to review your specific needs.

Film Width

Up to 119″

Film Roll Diameter

14″

Film Gauge

1.25 to 3 mil (typ)

Film Type

Other Film Specifications

Clear or randomly printed