The Duravant family of operating companies serve the food processing, packaging and material handling segments.

Arpac Brand PC-2500 Model Case and Tray Packer

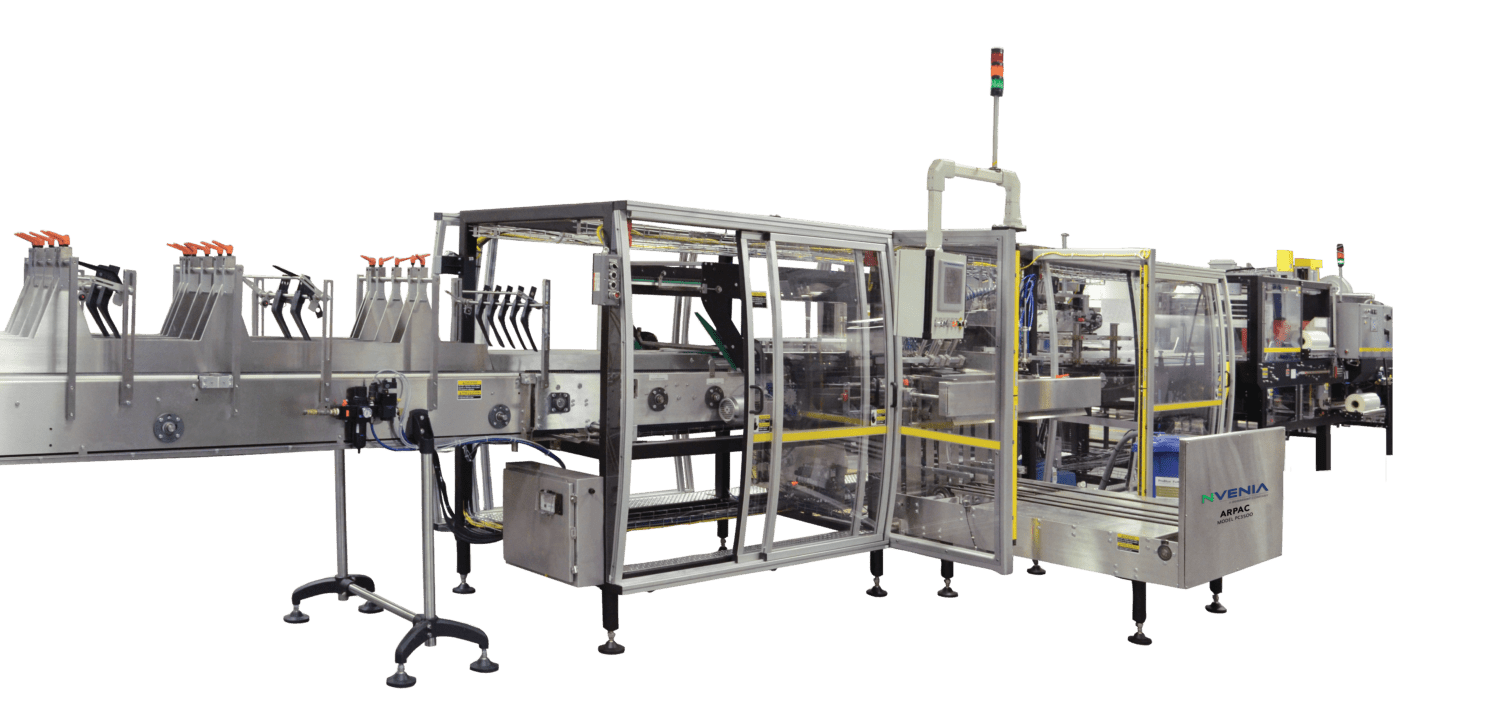

Our PC-2500 Model is a high performance continuous motion wraparound case and tray packer capable of reaching speeds of up to 25 cases/trays per minute.

This process uses up to 20% less corrugated material as compared to top load regular slotted cases (RSCs) resulting in significant annual material savings. This rugged machine reduces labor, increases productivity, reduces packaging costs and integrates easily into new or existing packaging lines.

The PC-2500 works well with metal cans, paper cans, glass jars, glass bottles, plastic jars and plastic bottles. The system collates the product, loads the product into a case or tray, and closes them with hot-melt glue.

Are you interested in this product?

We are here to help.

Features

Standard

- 5-axis servo driven system

- Compact design utilizes minimum floor space

- Encoder feedback for tight control

- Product infeed table utilizes a progressive separation system for smooth performance

- Dynamic top pressure device for rear containment

- Nordson ProBlue hot melt adhesive system

Options

- Servo lane divider

- Tray kit

- Automatic partition inserter

- Infeed product collations

- Complete automatic changeover

Corrugate

- B or C flute corrugation

- Burst strength: 150 or 200 lb per square inch

- Balanced outside and inside liners to avert warped blanks

- Minimum combined weight facings: 98 lb per square inch

- Maximum ¼” warp over 12” corrugated surface

Standard Specs

Standard Specs

Speed

Electrical Power Requirements

240V or 480VAC, 3 Ph, 60 Hz

Compressed Air Requirements

20 SCFM @ 80 psi

Product Requirements

- Minimum product size: 3″ W x 4.7″ L x 4.3″ H

- Maximum product size: 5″ W x 13.75″ L x 14.75″ H

- Minimum blank width: 11″ to 27.5″

- Maximum blank length: 26″ to 54″

- Tray wall height: 1 1/2″ – 6″