The Duravant family of operating companies serve the food processing, packaging and material handling segments.

Arpac Brand DPM Model Wraparound Case and Tray Packer

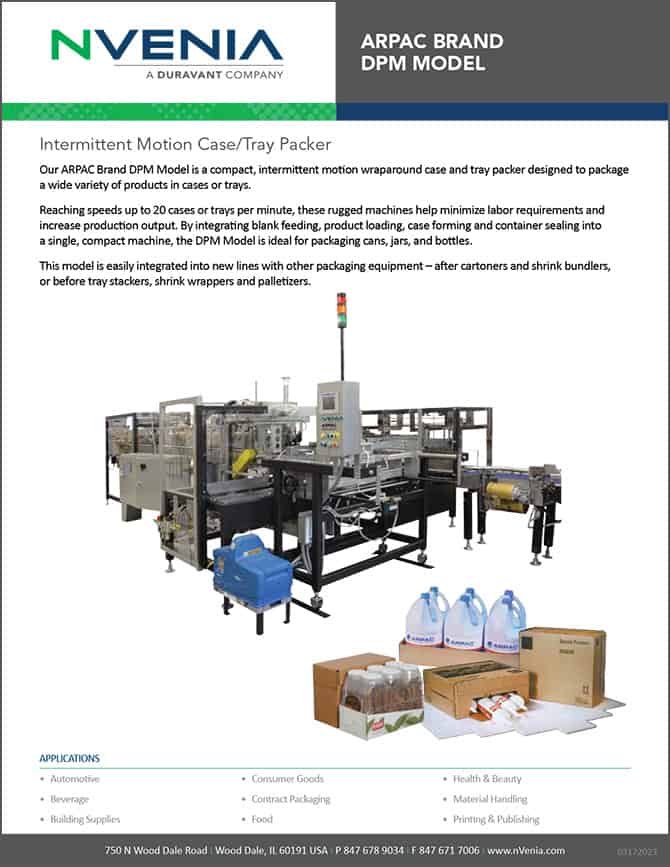

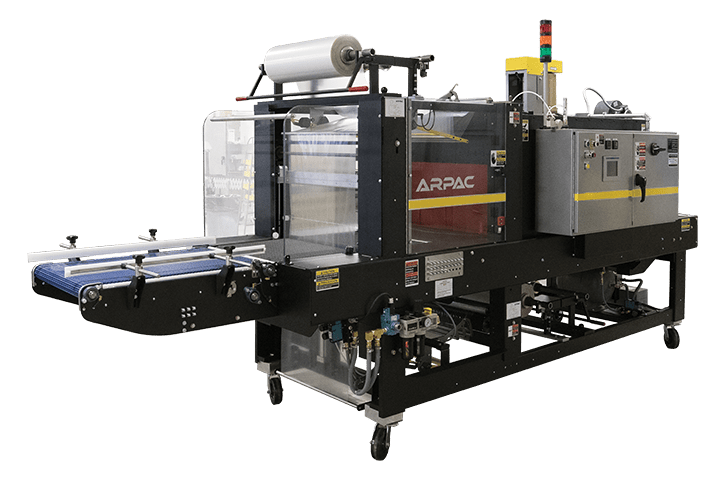

Our Arpac Brand DPM Model is a compact, intermittent motion wraparound case and tray packer designed to package a wide variety of products in cases or trays.

Reaching speeds up to 20 cases or trays per minute, these rugged machines help minimize labor requirements and increase production output. By integrating blank feeding, product loading, case forming and container sealing into a single, compact machine, the DPM Model is ideal for packaging cans, jars, and bottles.

This model is easily integrated into new lines with other packaging equipment – after cartoners and shrink bundlers, or before tray stackers, shrink wrappers and palletizers.

Are you interested in this product?

We are here to help.

Features

Standard

- Combines erecting, loading and glue sealing into one system

- Heavy-duty rugged construction designed for high durability and 24/7 operation

- Baked on powder coat finish provides a durable scratch resistant surface and prevents corrosion

- Allen-Bradley® programmable logic controller

- Crank adjustable blank feed with precision scales for easy setup

- Zero clearance systems form a tight package, transforming a flat board to a wrap-around case or tray for superior product protection

- Squaring compression creates excellent package appearance

- Nordson ProBlue® hot melt adhesive system for superior application flexibility and adhesion

- Central point lubrication simplifies routine maintenance

Options

- Standard and customized infeeds

- Servo-Operated Drop Zone

- Vacuum Platen for electric turbine vacuum generator (No compressed air)

- Magnetic Platen

- FOL (Full OverLap) instead of RSC (Regular Slotted Case)

- Crank adjustable lanes

- Extended hopper

Corrugate

- B flute Kraft corrugation

- Burst strength: 150 or 200 lb per square inch

- Balanced outside and inside liners to avert warped blanks

- Minimum combined weight facings: 98 lb per square inch

- Maximum 1/4″ warpage over 12″ corrugated surface

Glue Type

- Food grade hot melt adhesive

- Transparent, odorless, granulated

- 0.5 – 1 second set time

- Ejected at 300º to 350ºF (160º to 180º C)

Standard Specs

Standard Specs

Speed

Up to 20 cases/trays per minute

Electrical Power Requirements

230 or 460VAC, 3 Ph, 60 Hz

Compressed Air Requirements

Case Size Range

Minimum Case Size: 9″ W x 5″ L x 3″ H

Maximum Case Size: 20″ W x 14″ L x 10″ H

Tray Size Range

Minimum Tray Size: 9″ W x 7″ L x 3″ H

Maximum Tray Size: 20″ W x 14″ L x 10″ H