The Duravant family of operating companies serve the food processing, packaging and material handling segments.

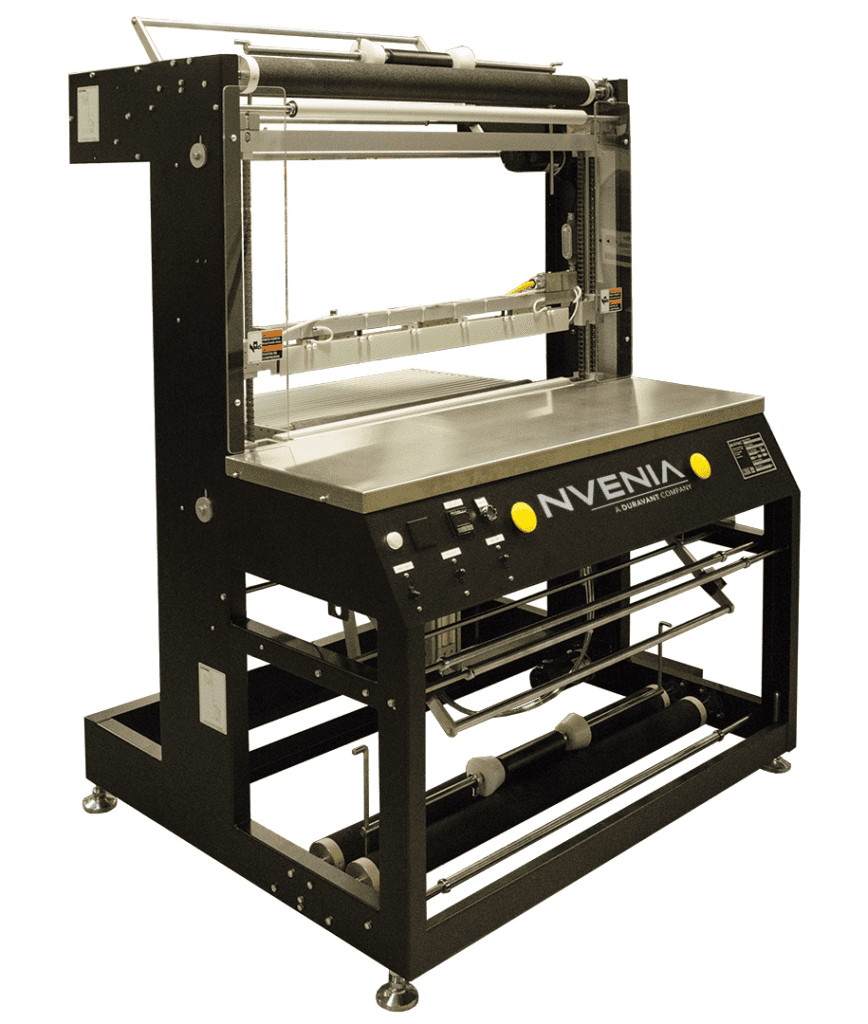

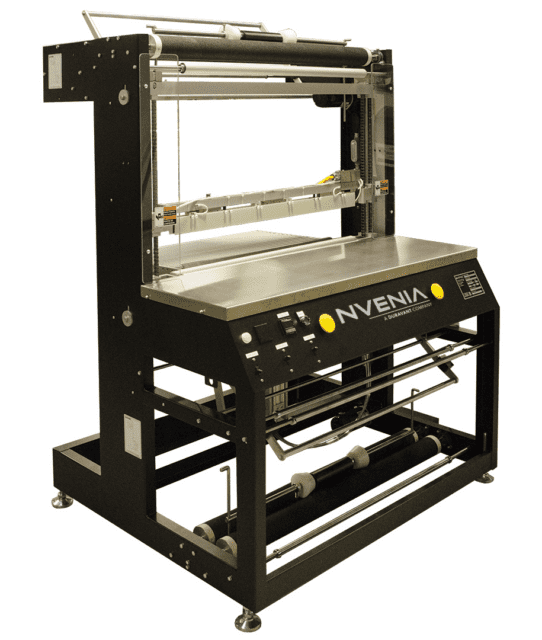

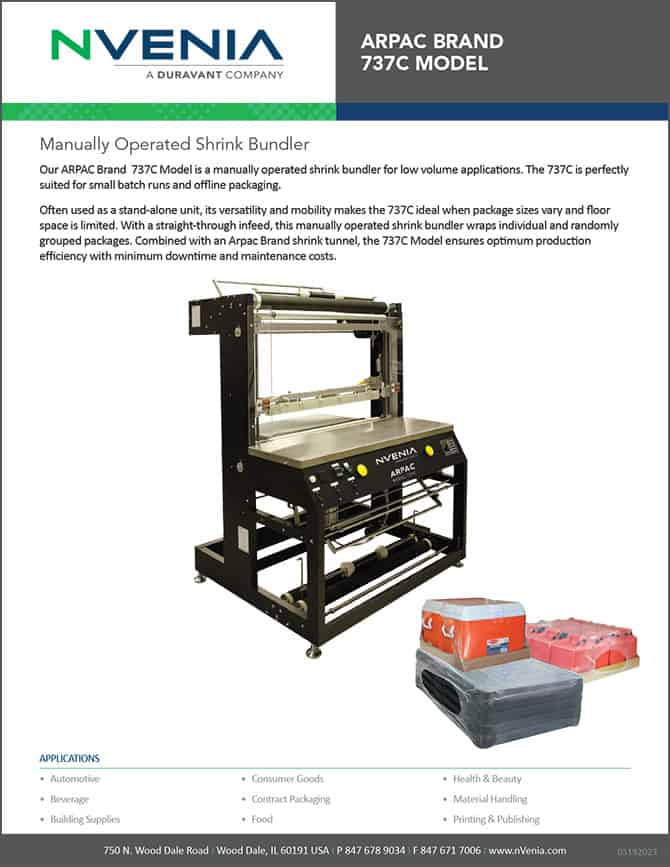

Arpac Brand 737C Model Shrink Bundler

Our Arpac Brand 737C Model is a manually operated shrink bundler for low volume applications. The 737C is perfectly suited for small batch runs and offline packaging.

Often used as a stand-alone unit, its versatility and mobility makes the 737C ideal when package sizes vary and floor space is limited. With a straight-through infeed, this manually operated shrink bundler wraps individual and randomly grouped packages. Combined with an Arpac Brand shrink tunnel, the 737C Model ensures optimum production efficiency with minimum downtime and maintenance costs.

Are you interested in this product?

We are here to help.

Features

Standard

- Ultra-compact rugged steel construction

- Safety system on seal jaws prevents seal jaw or package damage in case of product jams

- Adjustable seal bar opening allows operator to raise or lower seal line to improve package appearance

- Powered film feed – top and bottom rolls automatically adjust to varying depths and heights of intermixed bundles

- Seal cleaning film cut off hot knife burns through film cleanly with no film residue build up on the knife

Options

- Powered discharge conveyor

- Casters for easy machine portability

- Extended Dead Plate Infeed Table

- Extended Idler Roller Discharge

- 460VAC power

- Auxiliary E-Stop

- Spring loaded compression rollers

Standard Specs

Standard Specs

Speed

Manually fed and manually operated seal bars or up to 15 bundles per minute

Electrical Power Requirements

230VAC, 1Ph, 60Hz, 15A

Compressed Air Requirements

80 psi, 5 SCFM

Product Range

Film Roll Diameter

Up to 14″ with a 3″ core

Film Gauge

1-3 mil

Film Type

Low density polyethylene (L.D.P.E.)

Other Film Specifications

Clear or randomly printed