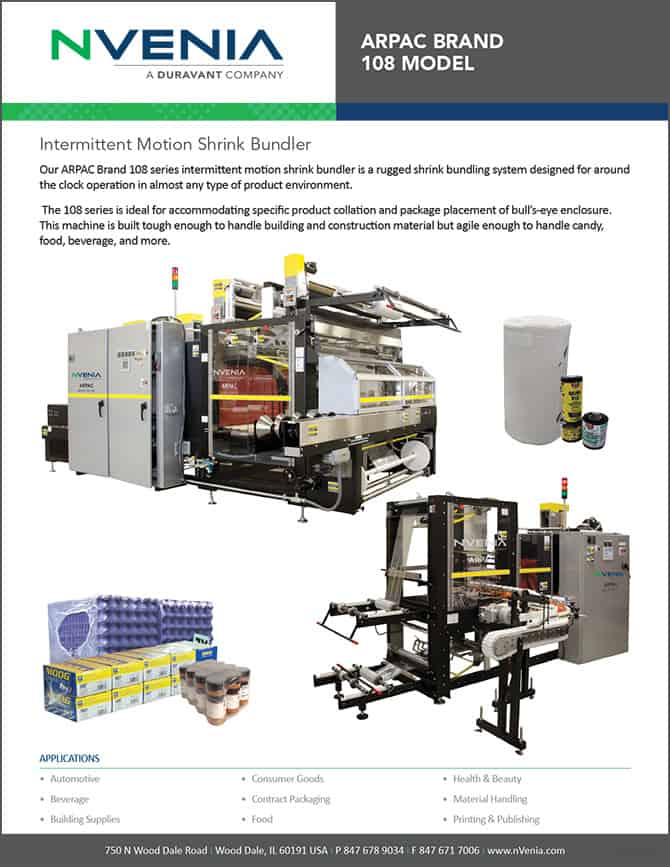

The Duravant family of operating companies serve the food processing, packaging and material handling segments.

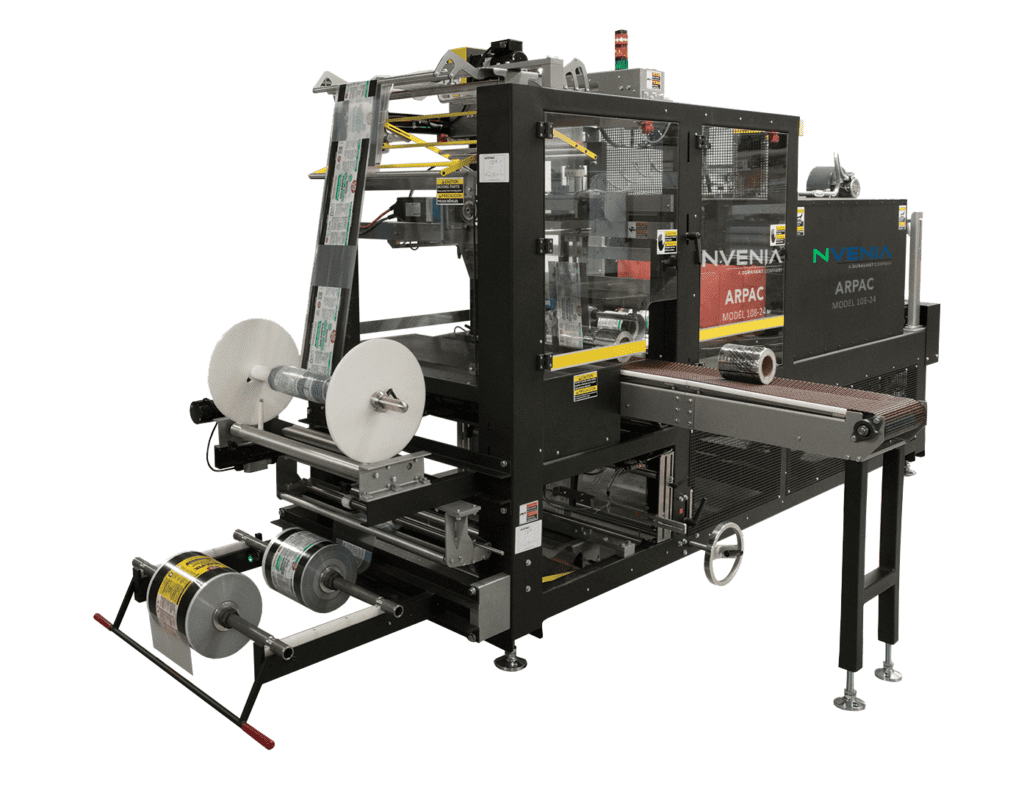

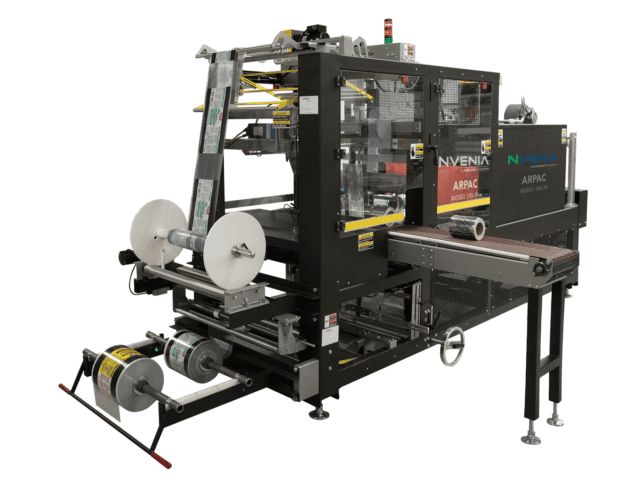

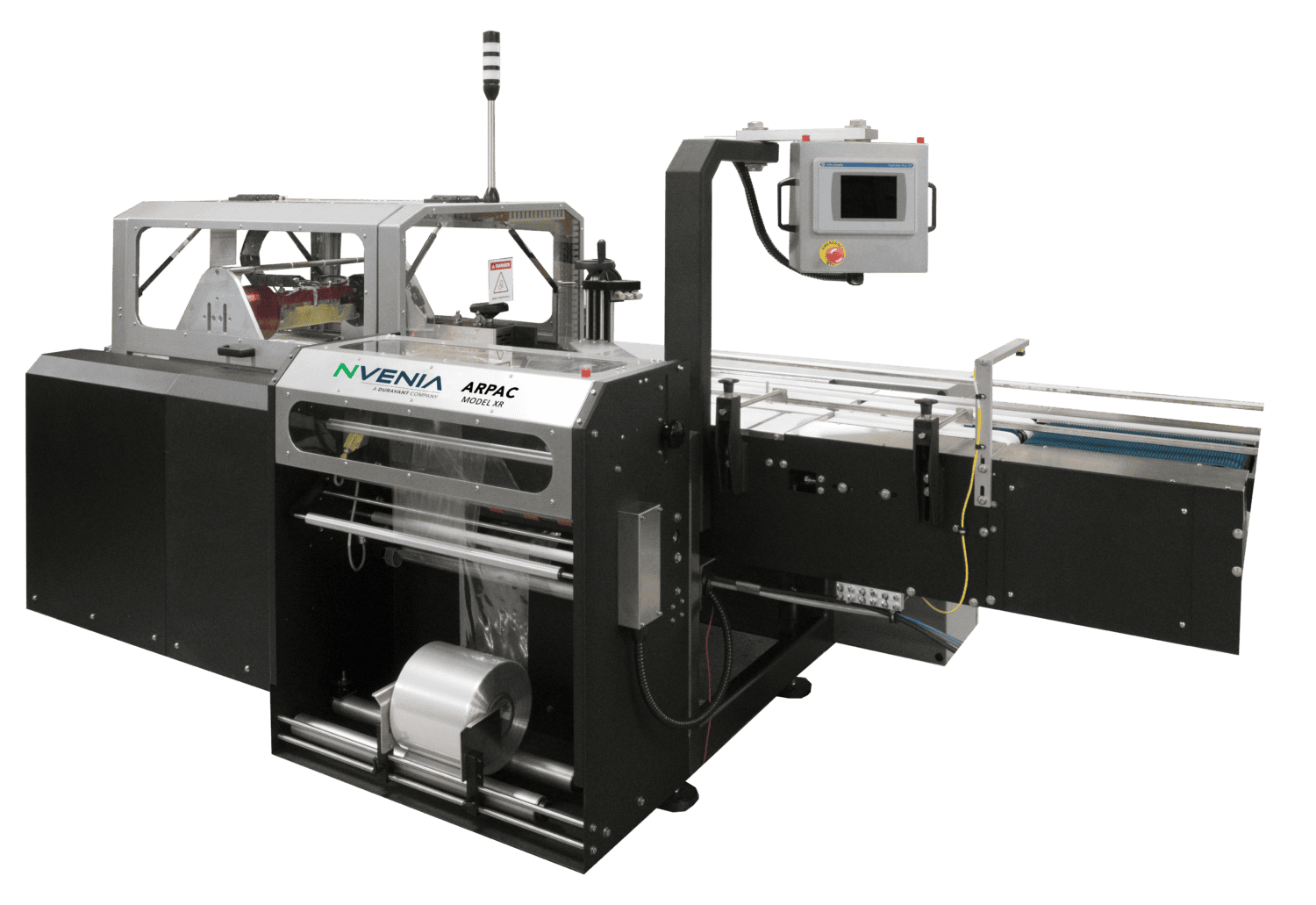

Arpac Brand 108 Model Shrink Bundler

Our Arpac Brand 108 model is an intermittent motion shrink bundler designed to be a rugged and durable system for around the clock operation in almost any type of product environment.

The 108 is ideal for accommodating specific product collation and package placement of a bullseye enclosure. This machine is built tough enough to handle building and construction materials, but agile enough to handle candy, food, beverage, and more.

Are you interested in this product?

We are here to help.

Features

Standard

- Single frame welded steel construction designed for 24/7 operation

- Infeed conveyor with sprocket driven plastic modular chain belts

- Non-telescoping top and bottom film racks accommodate a total of four 14″ diameter rolls of film

- Tool-less film roll core chucks to secure film to supply roll shaft

- Low inertia dancer bar system with nVenia’s original straight-through quick thread design

- Steel seal frame with high capacity, progressive damping shock absorbers

- Crank adjustable seal line height

- nVenia designed coil heating elements contact more airspace for greater efficiency

- Quick change, pull out tunnel heater assembly accessible from electrical cabinet

- Tunnel blower motor separated from turbine for cool operation and long motor life

- Turbo cooling at tunnel exit for faster film curing

Options

- Standard or custom infeed types

- Customizable seal bar width and maximum film roll width

- Servo driven seal frame and servo driven main product pusher

Standard Specs

Standard Specs

Speed

Up to 20 ppm, product dependent

Electrical Power Requirements

460VAC, 3 Ph, 60 Hz

Compressed Air Requirements

80 psi

Product Range

Completely customizable width length and height for almost any application requirements

Film Width

27″ max

Film Roll Diameter

14″ max OD with 3″ core

Film Gauge

1.5 – 2.5 mil

Film Type

Low density polyethylene (L.D.P.E.)

Other Film Specifications

Clear, randomly printed or print registered