The Duravant family of operating companies serve the food processing, packaging and material handling segments.

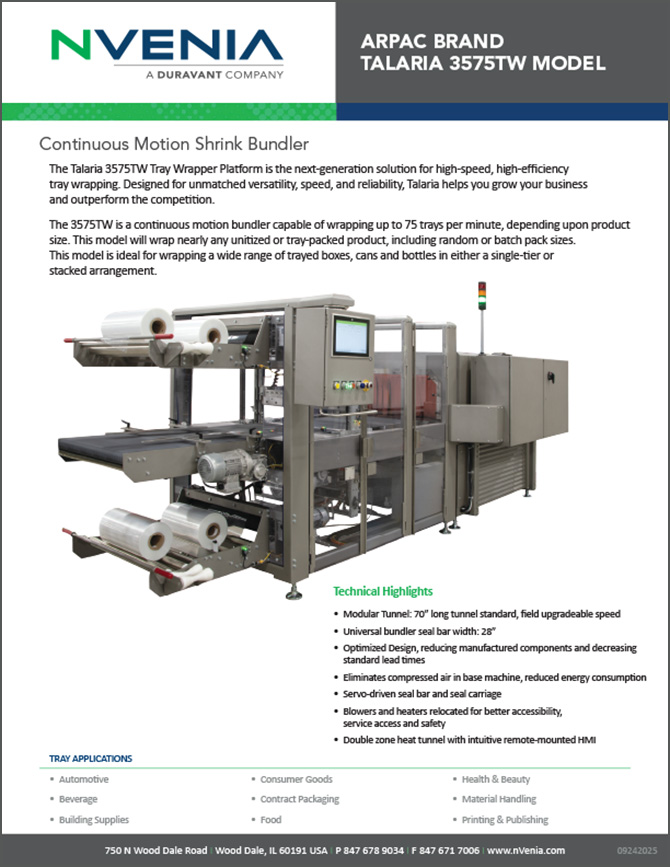

ARPAC Brand Talaria 3575TW Model

The Talaria 3575TW Tray Wrapper Platform is the next-generation solution for high-speed, high-efficiency tray wrapping. Designed for unmatched versatility, speed, and reliability, Talaria helps you grow your business and outperform the competition.

The 3575TW is a continuous motion bundler capable of wrapping up to 75 trays per minute, depending upon product size. This model will wrap nearly any unitized or tray-packed product, including random or batch pack sizes. This model is ideal for wrapping a wide range of trayed boxes, cans and bottles in either a single-tier or stacked arrangement.

Technical Highlights

• Modular Tunnel: 70” long tunnel standard, field upgradeable speed

• Universal bundler seal bar width: 28”

• Optimized Design, reducing manufactured components and decreasing standard lead times

• Eliminates compressed air in base machine, reduced energy consumption

• Servo-driven seal bar and seal carriage

• Blowers and heaters relocated for better accessibility, service access and safety

• Double zone heat tunnel with intuitive remote-mounted HMI

Are you interested in this product?

We are here to help.

Features

Features

• Heavy-duty rugged construction designed for high durability and around-the clock operation

• Laser cut and CNC machined components for maximum precision

• Powder coat finish that provides a durable scratch resistant surface and prevents corrosion

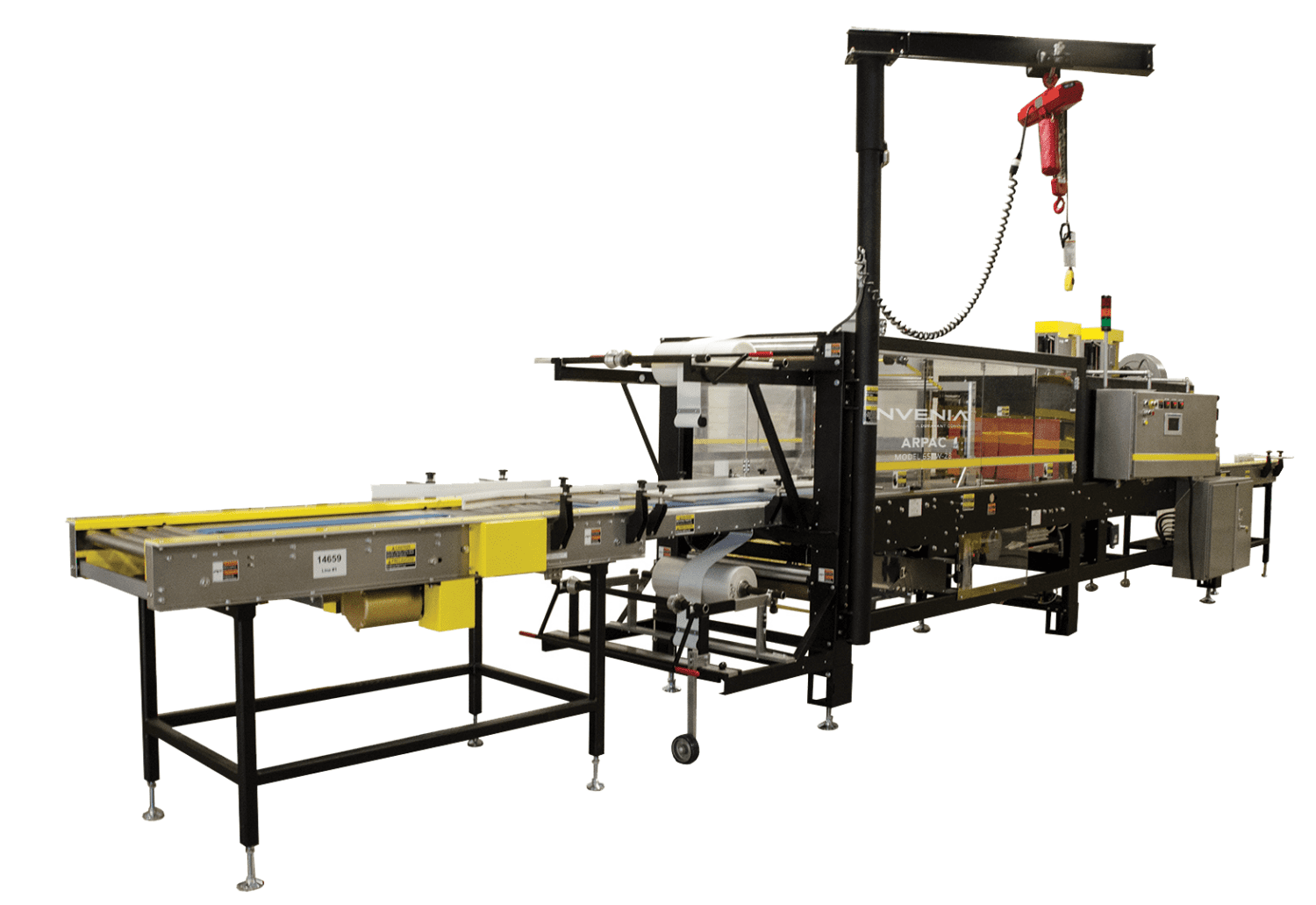

• Compact, two-frame design (wrapper with integrated tunnel)

• Allen-Bradley® OPTIX operator interface with color touchscreen, message display and self-diagnostics

• Digital controls ensure fast and accurate setup of conveyor speeds, timing, and temperature settings when changing product size and film

• Bypass mode allows product to pass through the machine without being wrapped and without heating the tunnel

• Low film alert warns that a film changeover will soon be necessary

• Durable Intralox conveyor belts eliminate tracking problems

• Seal frame opening for 10″ product

• Dual stage belt infeed conveyor

• 14″ diameter inline film racks for easy film loading

• Simple film threading procedure

• 70″ dual zone shrink tunnel (base model)

• Cooling feature at the tunnel exit for immediate product handling

• NEMA 12 electrical cabinet and controls

Options

Options

Options

• Jib crane to assist with film loading

• Side mounted film cradle with manual splicing bar for easy film loading at slower speeds

• Seal gap bridge, roller or telescoping, for product 3″ to 6″ L

• Side smoothing rollers

• Telescoping bridge

• Zero tension film feed

• Tunnel extension

• Custom elevation

• Auxiliary (4) button panel

• Auxiliary E-stop

• Air conditioning

• UL panel

• Adjustable product guides for pacing conveyor

• Splice bar

• Multiple height eye tree

Standard Specs

Standard Specs

Specifications

• Speed: Up to 75 trays per minute

• Electrical: 460 VAC, 3 Ph, 60 Hz

• Max. film width: 27″ single-wound

• Clear or randomly printed

• Max. film roll diameter: 14″ with a 3″ core

• Max. film gauge: 4 mil.

• Film type: low density polyethylene (L.D.P.E.)