The Duravant family of operating companies serve the food processing, packaging and material handling segments.

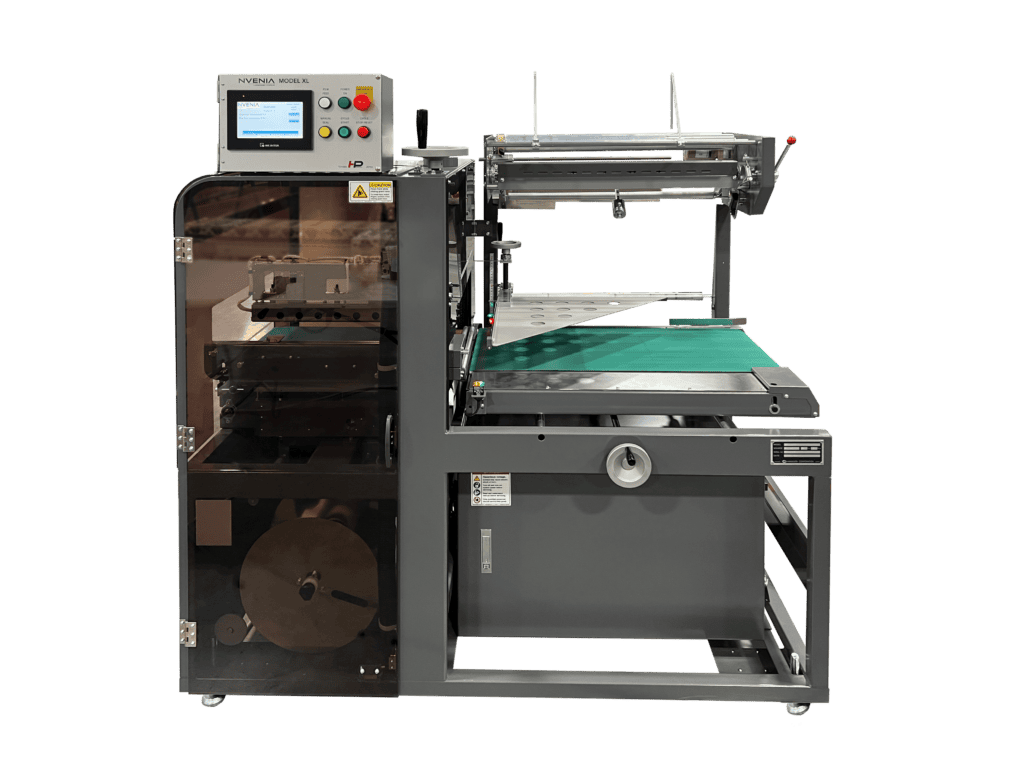

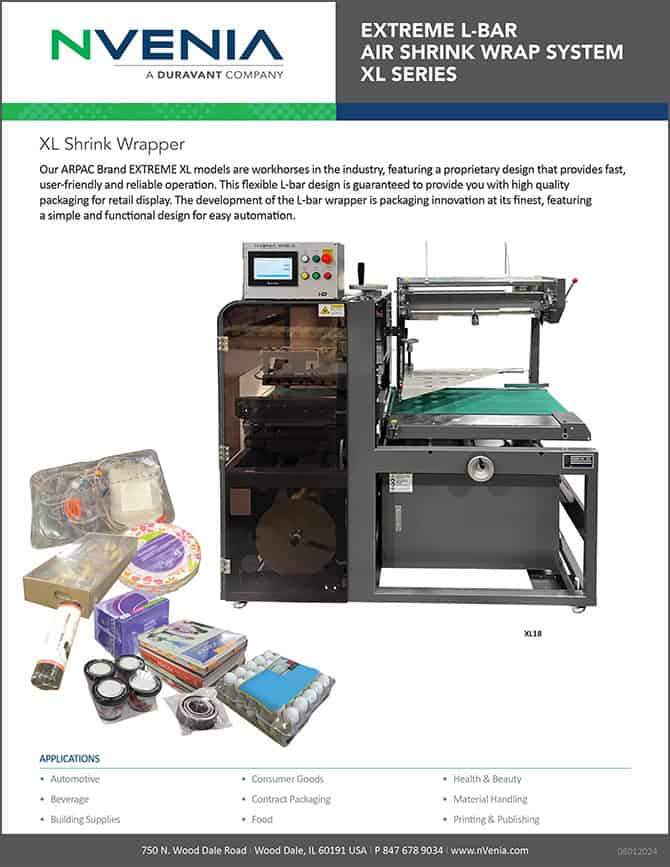

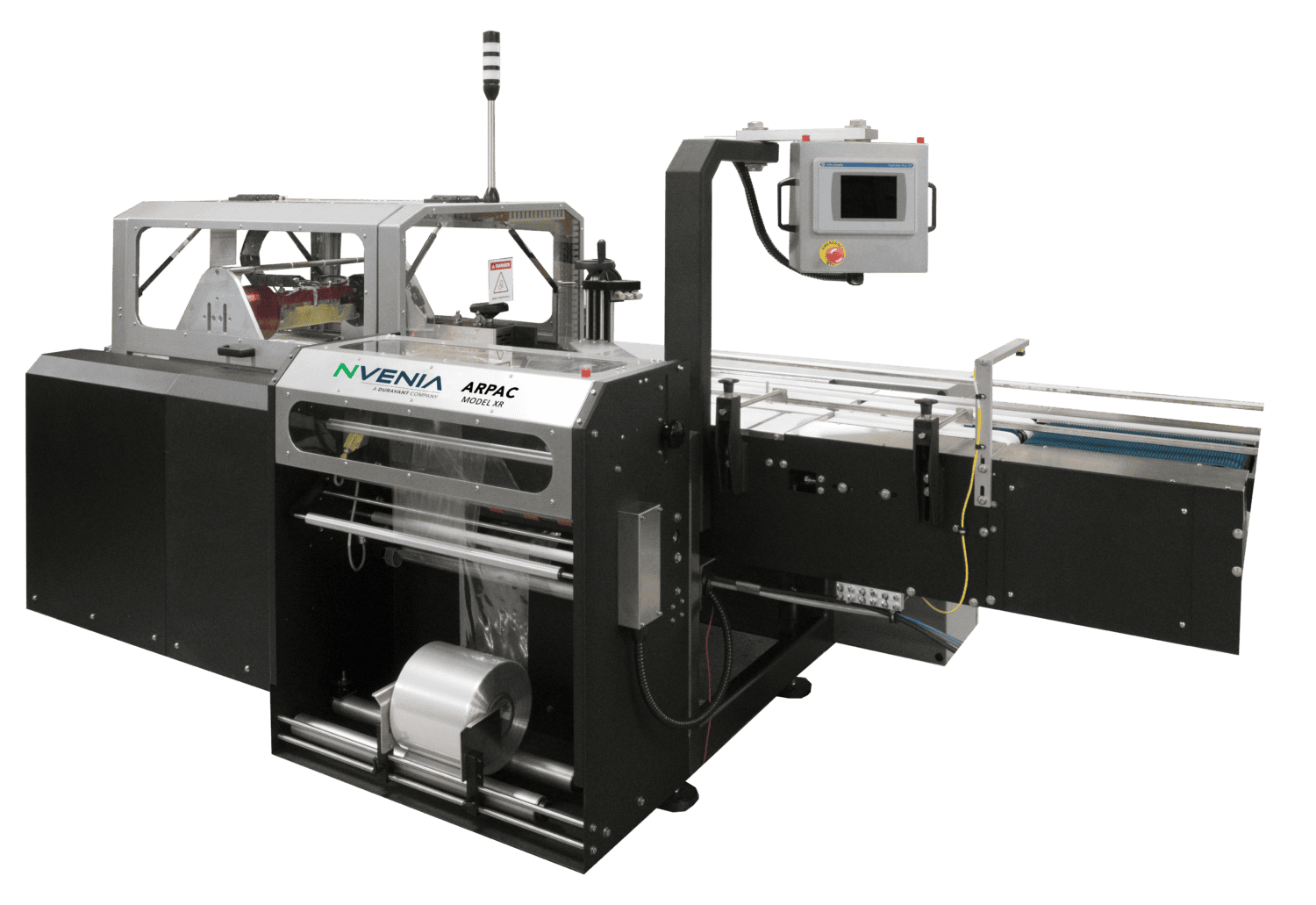

EXTREME XL Series L-Bar Air Shrink Wrap System

Our ARPAC Brand EXTREME XL models are workhorses in the industry, featuring a proprietary design that provides fast, user-friendly and reliable operation. This flexible L-bar design is guaranteed to provide you with high quality packaging for retail display. The development of the L-bar wrapper is packaging innovation at its finest, featuring a simple and functional design for easy automation.

Are you interested in this product?

We are here to help.

Features

Features

- Welded steel frame in a compact size for space efficiency

- Guillotine style hot knife seal bar design – straight pull vs. cantilever ensures highest quality seal

- Single point adjustment seal height with stroke-limiting automatic seal cylinder

- Seal height calibration automatically determines proper seal head cushioning

- Configurable PLC with color touchscreen interface

- Easy load film cradle with on demand powered film feed

- Film pinch roller positioned ahead of seal head eliminates film breaks/tears

- Adjustable legs with casters

Standard Specs

Standard Specs

Specifications

- Max speed: 35 packages per minute

- Electrical power requirements: 220 VAC, 1 Ph, 60 Hz

- XL18 electrical power requirements: 220 VAC, 1 Ph, 60 Hz

- XL26 electrical power requirements: 220 VAC, 1 Ph, 60 Hz

- Compressed air requirements: 80 psi, 5 SCFM

- XL18 machine dimensions: 40″ W, 65″ L, 63″ H

- XL18 shipping weight: ~1,200 lbs.

- XL26 machine dimensions: 46″ W, 79″ L, 65″ H

- XL26 shipping weight: ~1,600 lbs.

Options

- Closing conveyor for short length product

- Lower film cradle for ergonomic loading

- Reverse flow (L to R)

- Food approved infeed and discharge belts

Package Size Range

- XL18 product range:

- Min: 1.5″ W x 4″ L x 0.25″ H

Max: 15″ W x 18.5″ L x 6″ H

- Min: 1.5″ W x 4″ L x 0.25″ H

- XL26 product range:

- Min: 1.5″ W x 4″ L x 0.25″ H

Max: 19″ W x 26.5″ L x 8″H

- Min: 1.5″ W x 4″ L x 0.25″ H

Film

- Film roll diameter: 12″

- 45-70 gauge polyolefin or 1-3 mil low density polyethylene

- XL18 film specifications: 24″ max., centerfold, B wind

- XL26 film specifications: 30″ max., centerfold, B wind