The Duravant family of operating companies serve the food processing, packaging and material handling segments.

Arpac Brand GI Series Shrink Bundlers

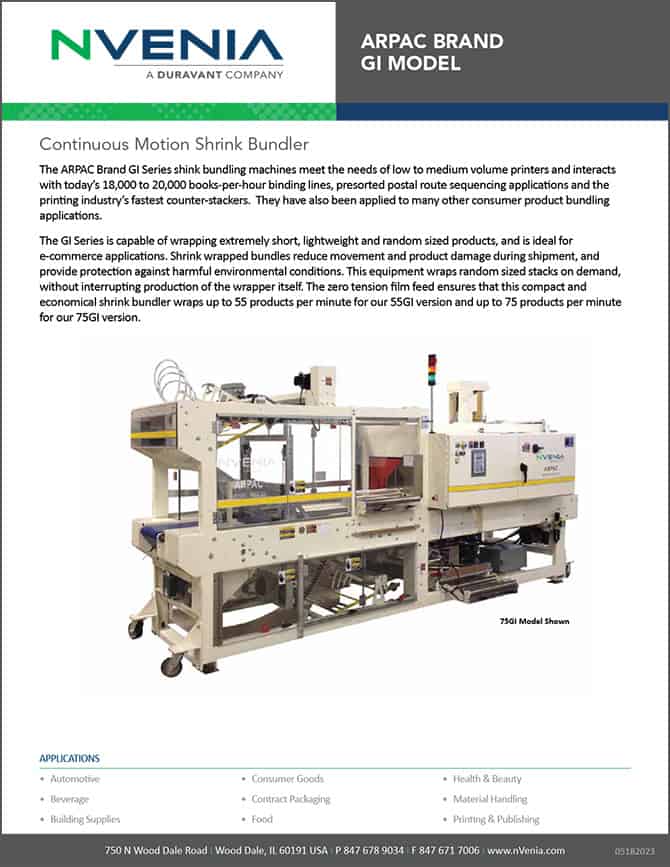

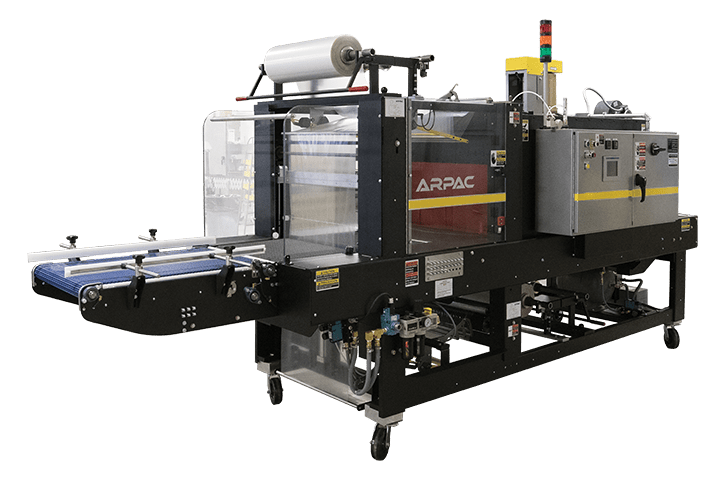

The Arpac Brand GI Series shink bundling machines meet the needs of low to medium volume printers and interacts with today’s 18,000 to 20,000 books-per-hour binding lines, presorted postal route sequencing applications and the printing industry’s fastest counter-stackers. They have also been applied to many other consumer product bundling applications.

The GI Series is capable of wrapping extremely short, lightweight and random sized products, and is ideal for e-commerce applications. Shrink wrapped bundles reduce movement and product damage during shipment, and provide protection against harmful environmental conditions. This equipment wraps random sized stacks on demand, without interrupting production of the wrapper itself. The zero tension film feed ensures that this compact and economical shrink bundler wraps up to 55 products per minute for our 55GI version and up to 75 products per minute for our 75GI version.

Are you interested in this product?

We are here to help.

Features

Standard

- Heavy-duty rugged construction designed for high durability and around-the-clock operation

- Compact, single frame design (wrapper with integrated tunnel)

- Laser cut and CNC machined components for maximum precision Powder coat finish

- Speeds up to 55 or 75 bundles per minute – model dependent

- Wraps random sized stacks on demand

- Continuous motion seal head provides smooth and quick transitions of product through the wrapper at high speeds

- Quick change plasma-coated seal bars for long life and easy maintenance

- Timing belt stabilized seal frame reduces maintenance and dirt accumulation

- Independent variable speed drives on the wrapper and tunnel

- Zero tension film feed prevents paper sheets or slippery magazines from shingling

- Side mounted film cradles for quick and easy film loading

- Shrink tunnel with product cooling section at the tunnel exit speeds film curing

- Durable Intralox conveyor belts eliminate tracking problems

- Low film alert warns that a film changeover will soon be necessary

- Allen-Bradley® programmable logic controller with nVenia standard operator interface

- Digital controls for fast and accurate setup

- NEMA 12 electrical cabinet and controls

- Central point lubrication allows for routine maintenance without stopping production

Options

- Split belt conveyor allows wrapping of short and lightweight products. This is typically used for e-commerce applications where product is placed on a chipboard or corrugated pad prior to wrapping

- Collating systems for grouping stacks of products together before they proceed through the seal frame and into the shrink tunnel

- Quick-change seal frame cylinder kit for higher speeds

- On certain high-gloss or stitched products, static charging may be necessary to hold the bundle together while shrink wrapping. Please consult ARPAC when this may be an issue

- Casters for machine portability

- Side smoothing roller to iron out odd shape bullseyes

Standard Specs

Standard Specs

Speed

Model 55GI: Up to 55 packages per minute

Model 75GI: Up to 75 packages per minute

Electrical Requirements

Model 55GI: 480VAC, 3Ph, 60Hz, 40A

Model 75GI: 480VAC, 3Ph, 60Hz, 50A

Other voltages available upon request

Compressed Air Requirements

Model 55GI: 80 psi, 30 SCFM

Model 75GI: 80 psi, 12 SCFM

Product Range

Minimum: 5″W x 7″ L x 3/16″H

Maximum: 12″W x 18″L x 10″ H

Film Roll Diameter

Up to 14″ with a 3″ core

Film Gauge

1.5 mil to 2.5 mil

Film Type

Low Density Polyethylene (L.D.P.E.)

Other Film Specifications

Single wound, clear or randomly printed

Machine Dimensions

Model 55GI: 150″ L x 52.25″ W x 76″ H

Model 75GI: 175.5″ L x 52.25″ W x 76″ H