The Duravant family of operating companies serve the food processing, packaging and material handling segments.

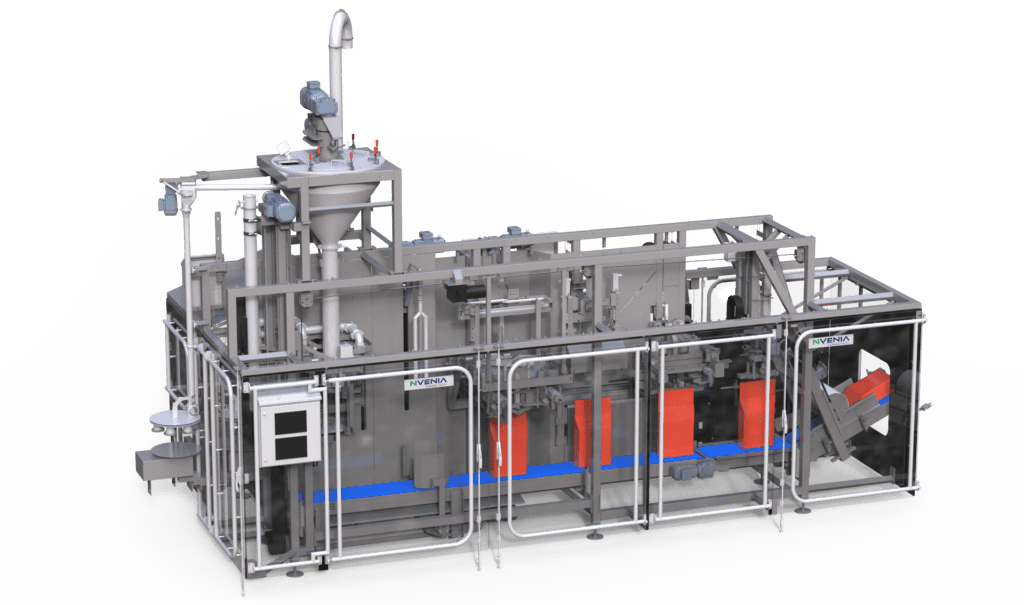

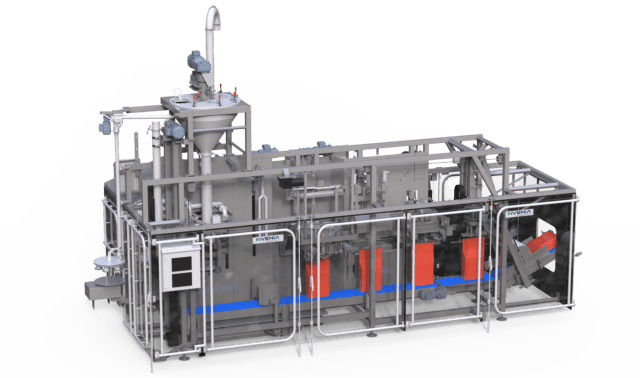

VLR-B Automatic Bagging System

nVenia’s VLR-B fully-automated bagging system is designed to eliminate the complexities associated with packaging powders into open-mouth bags. The technology behind the design of the VLR-B ensures a highly accurate dosing and precise dust control at every stage in the packaging process. The simple, yet highly durable design and construction makes change-over fast and easy for maximum throughput.

The Model VLR-B automatically picks and positions the empty bag onto the filling spout. Dosing is controlled by integral load cells on the servo controlled auger filler. The bag is filled from the bottom up to minimize dust generation and dust extraction ports are integrated at the fill point. Options include the introduction of nitrogen gas at the filling position to provide a longer shelf life and downstream product de-aeration to remove excess air from the product and bag for a more stable package. Next, the bag moves to a sealing station where the top of the bag is stretched, air-washed, and the inner liner is sealed with an impulse sealer. Finally, the filled bag moves into the integrated bag sealer section, which may be a pinch-top sealer, tape closure, a sewing machine, or a combination of these.

Are you interested in this product?

We are here to help.

Features

• Highly accurate, servo controlled dosing

• Dust collection/management at each stage in the process

• Bottom up fill method and fill tube seal minimize dust generation

• Fully welded, powder coated, structural steel frame

– product contact points in 304 stainless steel

• Easy to clean structure built with hygienic design principles

• Designed for ease of operation, adjustment, and maintenance

• Up to 500 programmable recipes

• Ethernet and WiFi connections for remote service

Standard Specs

Standard Specs

Machine Dimensions

12″9′ W X 20’9″ H X 33′ L

Speed

Up to 6 bags per minute

Bag Information

Empty Bag Size Range*:

• L 23-5/8″ (600 mm) to 39-3/8″ (1000 mm)

• W 15″ (380 mm) to 22-1/2″ (570 mm) or 17-3/4″ (450 mm) with gusset (Note: gussets will be inverted during sealing)

*Consult your regional sales manager for bags outside of provided range

Electrical Requirements

480VAC, 3 Phase, 60 Hz

Air Requirements

90 PSI air with 1.5″ connection

Accessories

Accessories

OPTIONS:

• Centralized dust extraction – combines all dust extraction zones to single outlet Integrated bag top correction and pinch-top sealer

• Integrated bag top sewing system with bag top cutter and crepe tape

• ATEX around filling point (3 foot radius)

• Additional stack stations for empty bags

• Integral product sampling unit to extract samples from the dosing hopper

• Bag top trim removal

• Gas flushing with nitrogen

• Full 304 stainless steel construction