The Duravant family of operating companies serve the food processing, packaging and material handling segments.

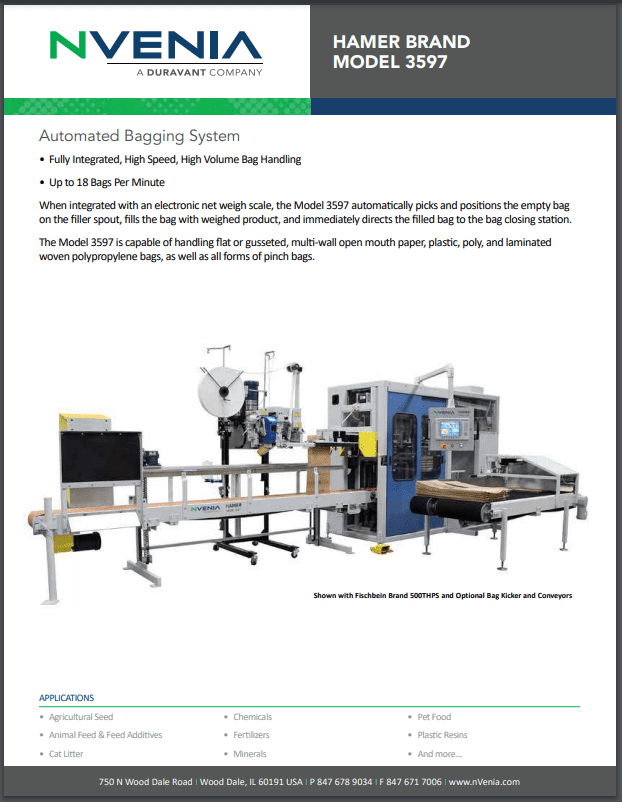

Hamer Brand Model 3597 Open Mouth Bagging Machine

Our Hamer Model 3597 Automated Bagging System provides fully automatic bag hanging and transfer for a wide variety of flat or gusseted, pre-made open-mouth paper, woven polypropylene and polyethylene bags. The Hamer Model 3597, when integrated with an electronic net weigh bagging scale or auger filling system, automatically picks and positions the empty bag on the filler spout, fills the bag with product, and immediately directs the filled bag to the bag closing station. This fully integrated bagging system is compatible with a wide range of products, and has a performance range up to 20 bags per minute.

Are you interested in this product?

We are here to help.

Features

Standard

- Processes a variety of flat or gusseted bags, including multi-wall paper, laminated woven polypropylene and pinch bags.

- Product change-over is fast, easy, and safe thanks to advanced touch screen controls and motorized adjustments.

- Auto bag index correction ensures the bag is centered under the spout prior to filling.

- The “no bag-no dump” feature prevents the machine from releasing product unless the bag is centered correctly, making for minimal product spills.

Options

- Integrated sealing conveyor

- Extended bag feed conveyor

- Special anti-corrosion package

- Automated tilt tray adjustments

- Network router

- Enhanced dust controls

- Tagger infeed assembly

- 575 VAC

- Data collection and reporting

Bag Types

- Pillow

- Gusseted

- Polyethylene – PE (6 mil minimum) bags

- Woven Polypropylene bags (Laminated non-porous)

- Woven Poly-Laminate bags (non-porous)

- Pinch Bottom Open Mouth (PBOM) bags

- Paper multiwall/Kraft bags

- Paper/Poly Lined bags

- BoPP/BOM

Bag Sizes

- Bag Width – 12” to 20”

- Bag Length – 20” to 40”

Bag Thickness

Minimum 6 mil

Free Bag Top

- Minimum 6 in (15.2 cm)

Standard Specs

Standard Specs

Dimensions

88 1/4″ (224 cm) H x 111″ (282 cm) W x 153″ (389 cm) L

Note: standard door swing is 39″ (99 cm) additional width and electrical enclosure requires 34″ (86 cm) in length at rear of machine

Speed

Up to 18 bags per minute, product and bag size dependent

Electric (NEMA 12)

460 VAC, 3 PH, 60 Hz

Air

45 CFM @ 100 PSI