The Duravant family of operating companies serve the food processing, packaging and material handling segments.

Blogs

Explore a variety of packaging industry thought leadership pieces from our internal subject matter experts, read compelling case studies, hear from our service techs about helpful maintenance tips and tricks and more here in the nVenia Blog. Do you have a question you would like answered? Or a subject matter in the packaging industry you would like to learn more about? Let us know!

Flour Producer Modernizes Milling Operations with FISCHBEIN Brand Equipment

06/09/2017

Effective Filling Technologies for Bagging Growing Media

05/09/2017

The nVenia FISCHBEIN Model 400 NS continues to lead sewing innovation for the Seed Bagging Industry

04/28/2017

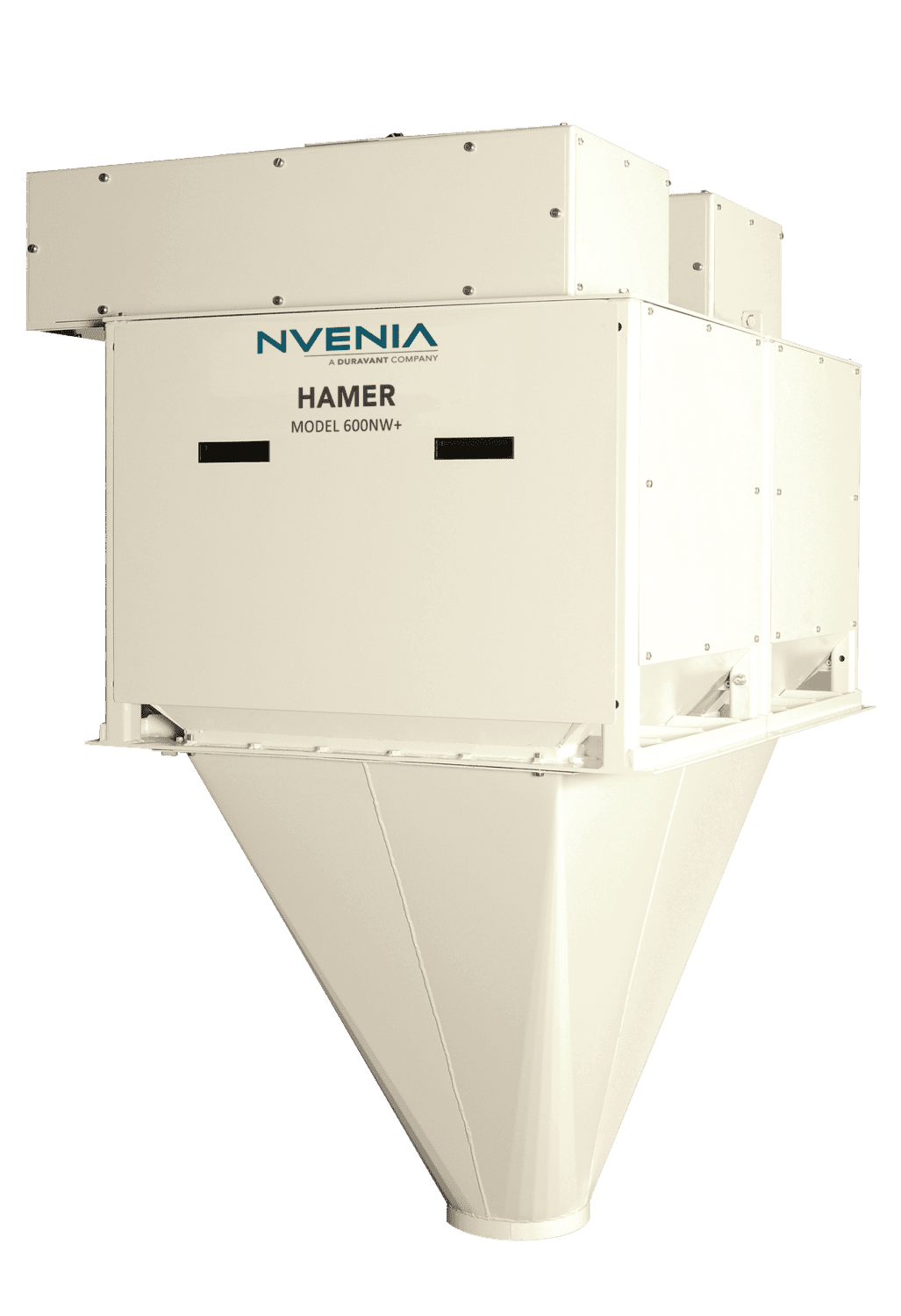

Feed Bagging Case Study: Kreamer Feed

03/18/2017

Packaged Ice Palletizing Case Study: Triangle Ice

03/07/2017

Pellet Fuel Bagging Case Study: Marth Wood Products

03/07/2017

Animal Feed Case Study: Form-A-Feed

02/01/2017

Fertilizer Bagging Case Study: American Plant Food Corporation

01/31/2017

Lawn and Garden Bagging Case Study: Markman Peat Improves Efficiency with Automation

01/20/2017

Chemical Bagging Case Study: Caspian Sulphur

01/20/2017

Chemical Bagging Case Study: CRI Catalyst Company

01/20/2017

Animal Feed Bagging Case Study: Kent Nutrition Group

12/01/2016