The Duravant family of operating companies serve the food processing, packaging and material handling segments.

Blogs

Explore a variety of packaging industry thought leadership pieces from our internal subject matter experts, read compelling case studies, hear from our service techs about helpful maintenance tips and tricks and more here in the nVenia Blog. Do you have a question you would like answered? Or a subject matter in the packaging industry you would like to learn more about? Let us know!

Industrial Film & Bag Producer Partnerships

10/28/2016

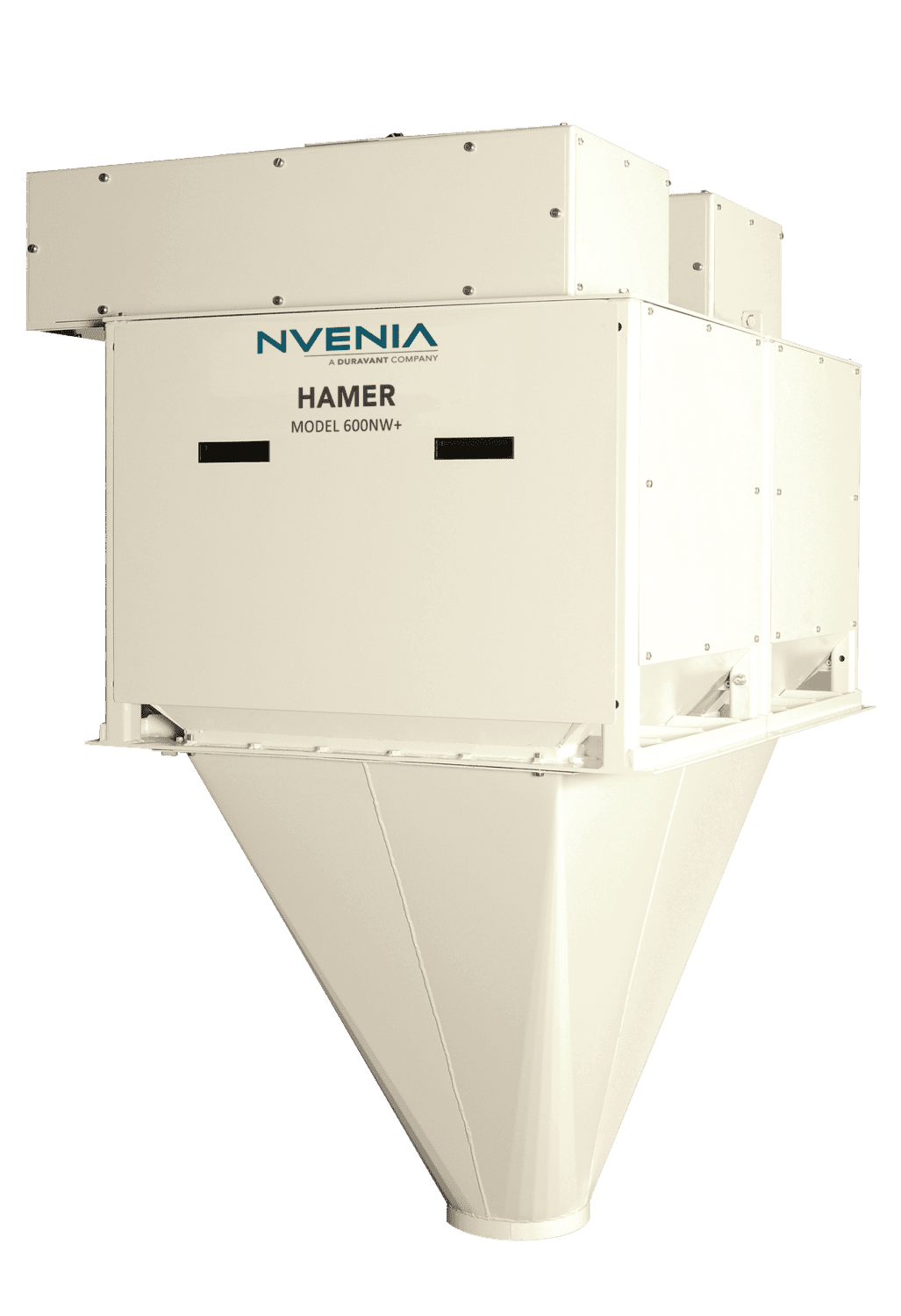

How to Determine The Correct Net Weigh Scale Feeder For Your Material

10/04/2016

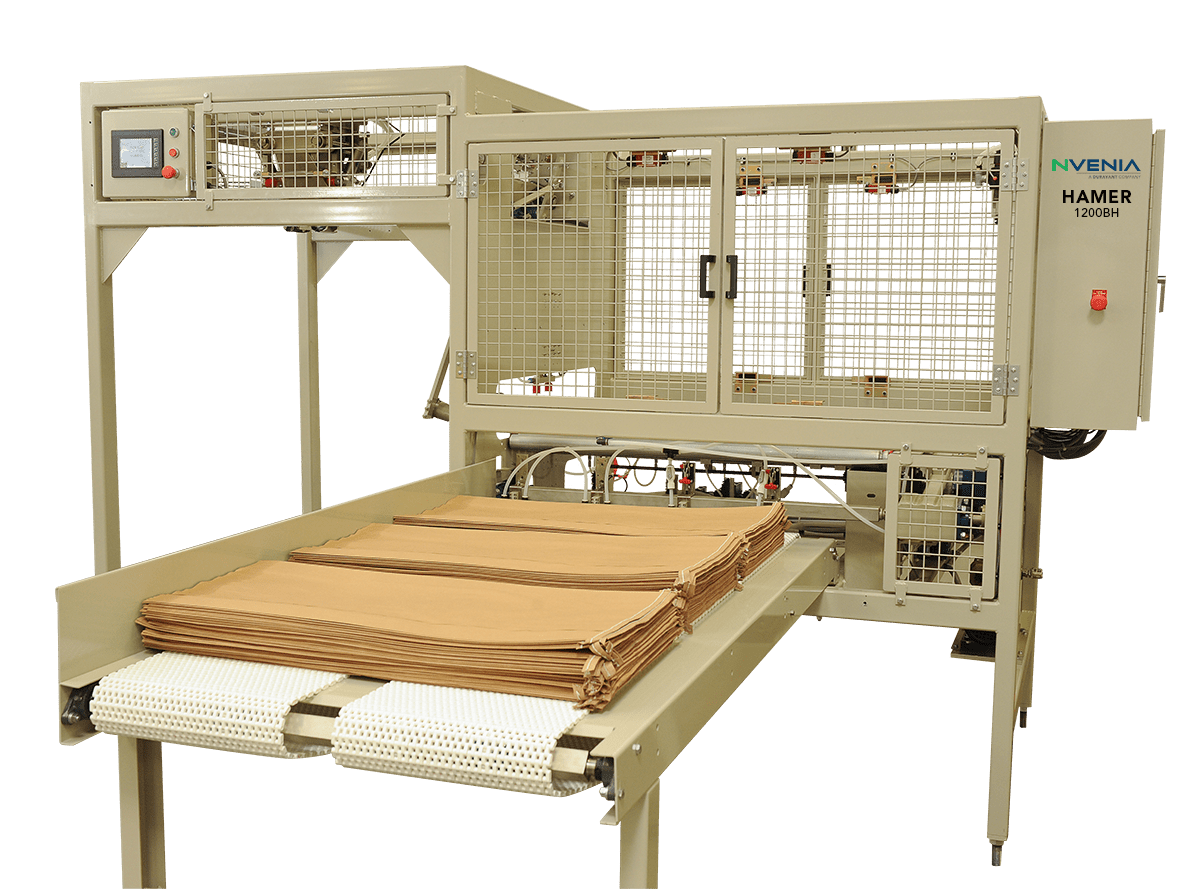

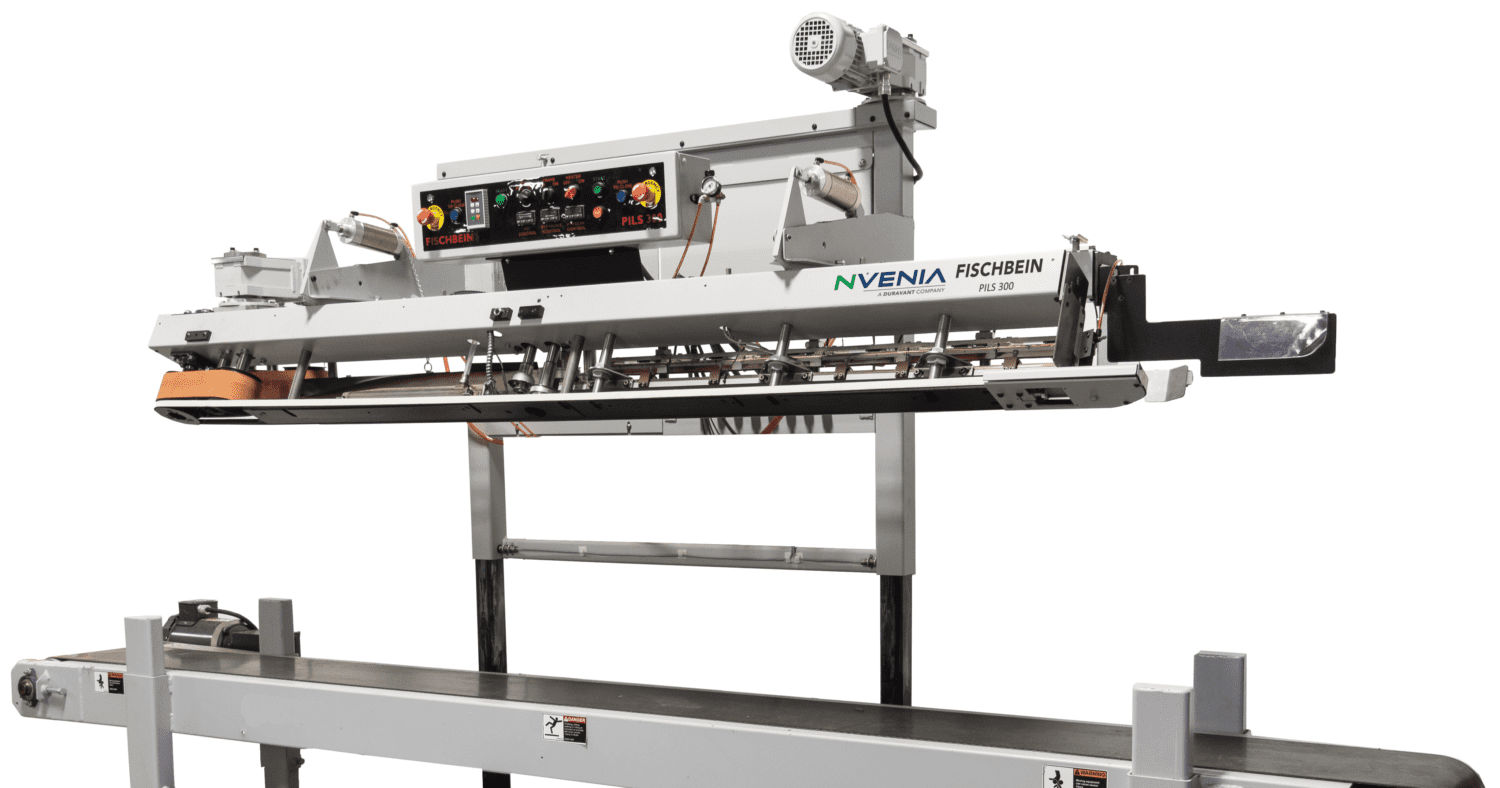

Innovative Upright Bag Conveyor Design Maximizes Production in Feed and Seed Plants

08/15/2016

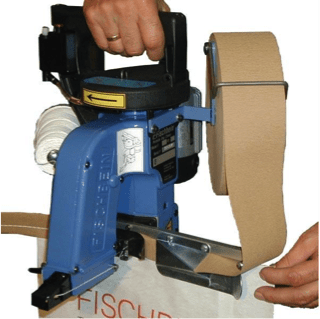

Fischbein F-Series Portable Bag closer: Unbeatable For Quality and Durability

08/10/2016

New Dura Thread Clipper: An Innovative Retrofit for Industrial Bag Top Sewing Applications

07/11/2016

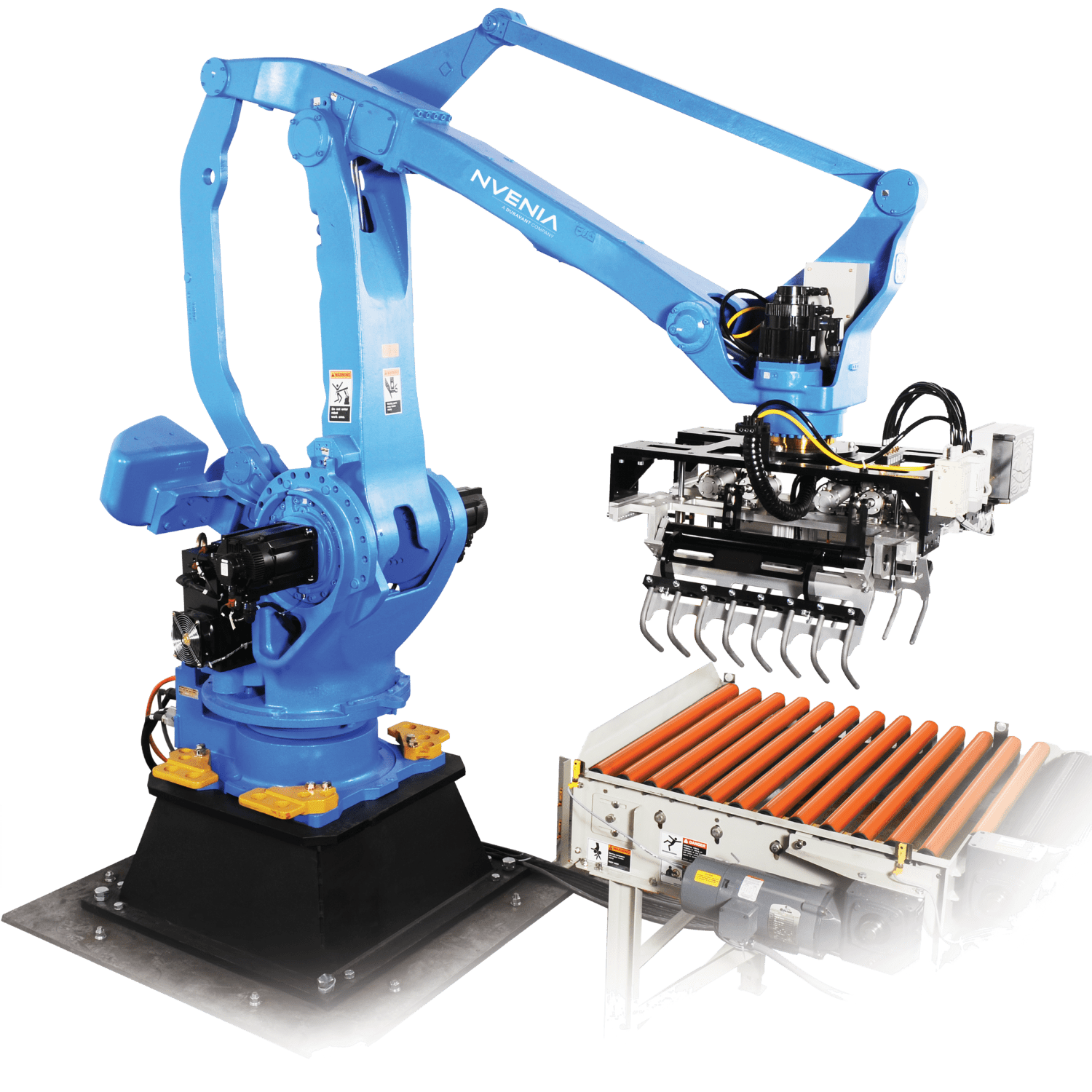

nVenia Robotic Bag Palletizers Continue To Improve Plant Efficiencies With New Enhancements

06/26/2016

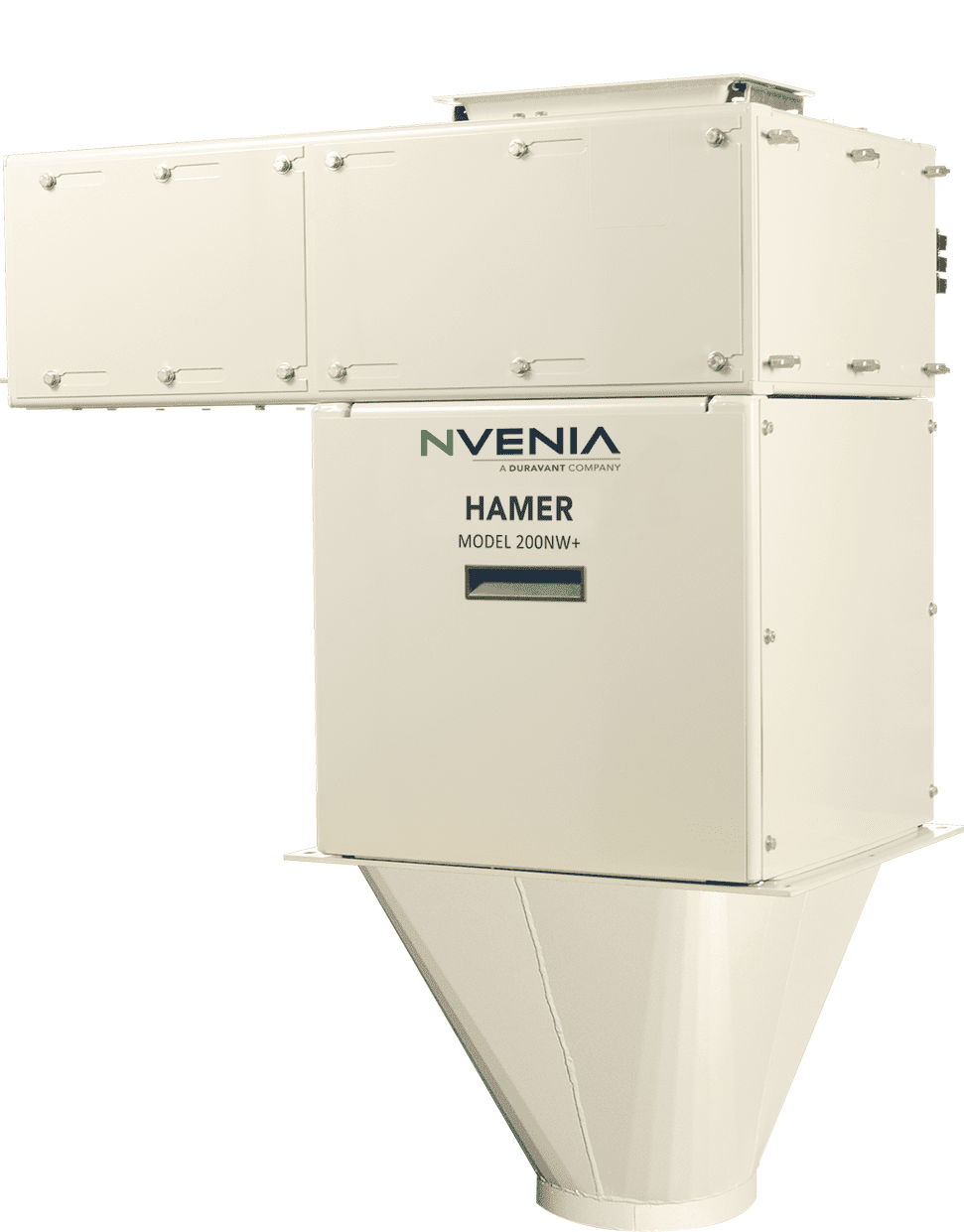

nVenia HAMER Brand 200NW+ Net Weigh Scale Innovation Expands Market Application Opportunities

06/01/2016

Hamer-Fischbein Named Top Yaskawa Motoman Robotics Integrator – Three Years

06/01/2016

Pinch Bag Closers Are a Smart Choice For Animal Feed Or Feed Additives

04/16/2016

Aggregate Bagging Case Study: Pavestone® Automates Bagging Plants Nationwide

03/06/2016

Case Study: American Rock Salt Modernizes Salt Bagging Facility

03/06/2016

Hot Air Bag Sealer Replaces Band Sealers in Side Gusset Poly

02/26/2016