The Duravant family of operating companies serve the food processing, packaging and material handling segments.

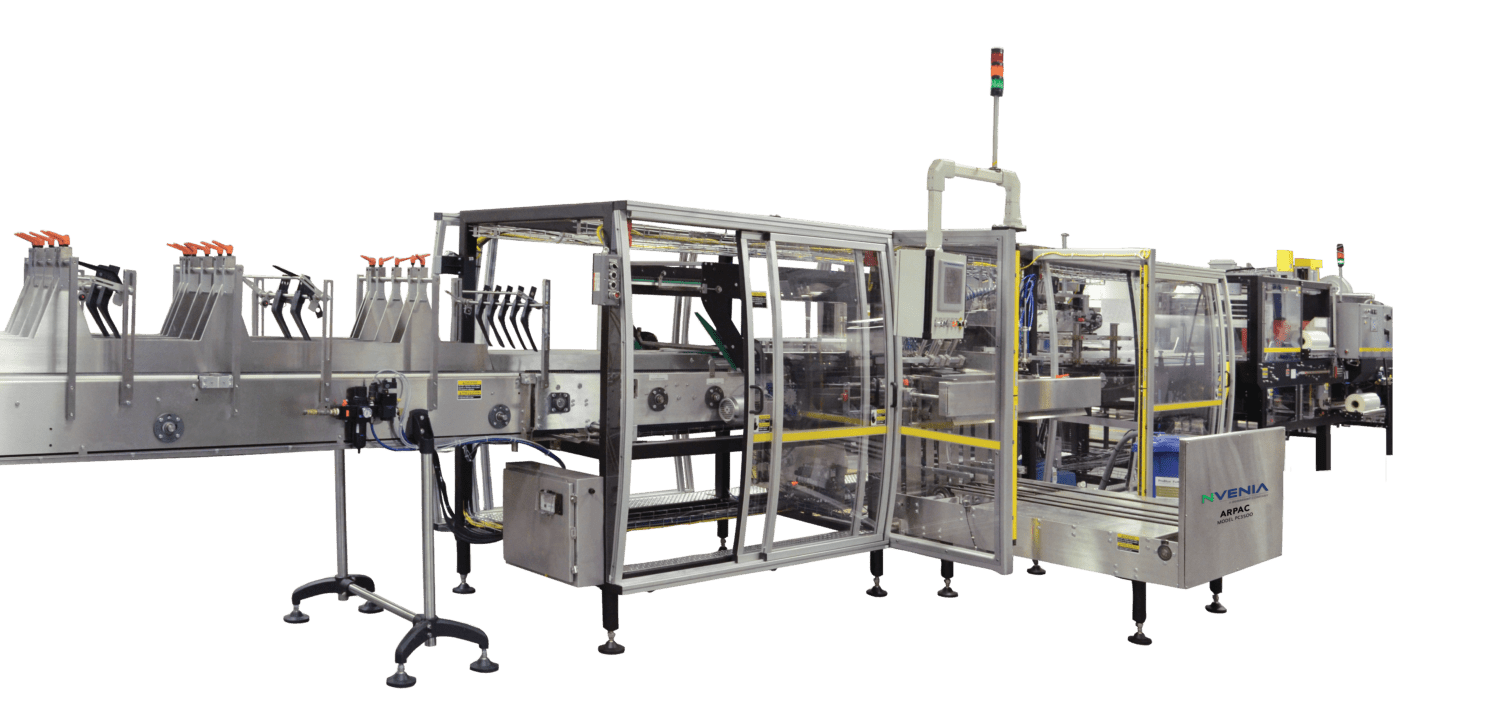

Arpac Brand MTE Model Tray Former

Our Arpac Brand MTE Model is an intermittent motion tray former.

The MTE Model automatically erects trays using a hot melt glue system at speeds up to 25 trays per minute. This system is ruggedly built and compact in size with simple tool-less adjustments between tray sizes. The MTE Model is used in a variety of industries and can be easily integrated with other packaging equipment.

Are you interested in this product?

We are here to help.

Features

Standard

- Heavy-duty rugged construction designed for high durability and 24/7 operation

- Nordson ProBlue® hot melt glue system

- Easy load and adjust 150 capacity blank hopper

- Positive blank control with Venturi vacuum pull-down system

- Quick tray punch changeover

- Tool-less changeovers with scales for setup repeatability

- Clear Lexan guard doors with interlocking safety system for operator protection and easy access

Options

- Power magazine with additional tray blank capacity

- Inclined conveyor for tray discharge

Corrugate

- B flute Kraft corrugation

- Burst strength: 150 or 200 lb. per square inch

- Balanced outside and inside liners to avert warped blanks

- Minimum combined weight facings: 98 lb. per square inch

Glue Type

- Food grade hot melt adhesive

- Transparent, odorless, granulated

- 0.5 – 1 second set time

- Ejected at 300º to 350ºF (160º to 180º C)

Standard Specs

Standard Specs

Speed

Up to 25 trays per minute

Electrical Power Requirements

230VAC, 3 Ph, 60Hz (460VAC optional)

Compressed Air Requirements

80 psi at 40 SCFM

Product Dimensions

Min: 9″ W x 6″ L x 1.5″ H (or 7″ W if at least 8.5″ L)

Max: 30″ W x 20″ L x 6″ H

Blank Dimensions

Max 42″ W x 34″ L

Tray Height

1.5″ – 6″

Machine Dimensions

99″ L x 78″ W x 77″ H

Machine Weight

~1000 lbs (higher with options)